Do Paper Gaskets Need Sealant – Everything You Need To Know

If you’ve ever wondered whether paper gaskets need sealant. The answer is yes, paper gaskets need sealant in order to work correctly. Sealant helps to fill any gaps or holes in the gasket material, which prevents leaks. Leaks can cause all sorts of problems, ranging from decreased performance to complete device failure.

Paper gaskets are a vital component of many devices and machines. Without them, these devices would not be able to function properly. However, some people may question whether or not paper gaskets need sealant.

In some cases, leaks can even be dangerous. That’s why it’s important to make sure that your paper gaskets are properly sealed with a quality sealant.

Do Water Pump Paper Gaskets Need Sealant?

If you have a water pump paper gasket, it’s important to know if you need to use sealant on it or not. In most cases, no sealant is needed if the gasket is installed correctly. However, there are some instances where using a small amount of sealant can help create a stronger seal and prevent leaks.

If you’re unsure whether or not to use sealant, consult with a mechanic or automotive specialist.

Read More About: Can mice chew through foam sealant

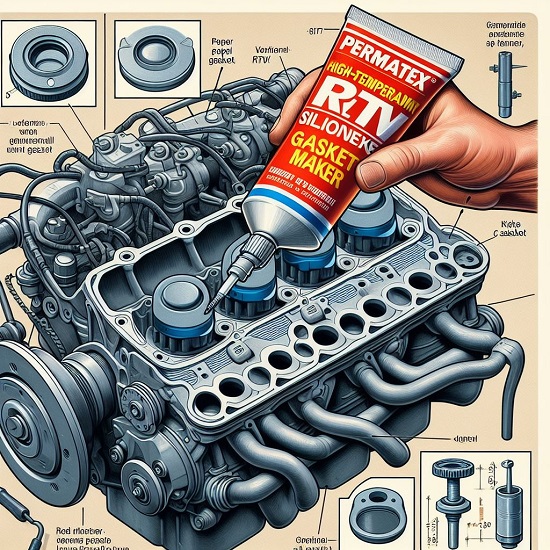

Should I Put Rtv on Paper Gasket?

If you’re wondering whether or not you should put RTV (room-temperature vulcanizing) silicone on your paper gasket, the answer is most likely yes. RTV silicone provides a better seal than just the paper gasket alone and will help to prevent leaks.

It’s important to note, however, that RTV silicone should only be used on dry surfaces – if either surface is wet, the RTV won’t cure properly and could cause leaks.

Do All Gaskets Need Sealant?

Not all gaskets need sealant, but it is generally a good idea to use some sort of sealant on any gasket that will be exposed to fluids or high temperatures. This is because even the best-made gaskets can leak over time if they are not properly sealed.

Sealants provide an extra layer of protection against leaks, and they can also help to fill in any small gaps or irregularities in the gasket material.

There are many different types of sealant available, so be sure to choose one that is compatible with the materials you are using.

Should You Silicone Paper Gasket?

There are a few things to consider when deciding whether or not to use a silicone paper gasket. First, what is the intended purpose of the gasket? If it is simply for decoration, then there is no need to use a silicone paper gasket and any other type of paper will suffice.

However, if the gasket is meant to provide a seal or barrier between two surfaces, then using a silicone paper gasket may be beneficial.

Silicone paper gaskets are able to withstand higher temperatures than other types of paper gaskets and provide a better seal against leaks. They are also more flexible and less likely to tear than other types of paper gaskets.

However, they are more expensive than other types of paper gaskets and can be difficult to find in stores. If you decide to use a silicone paper gasket, make sure to follow the manufacturer’s instructions carefully in order to get the best results.

How to Properly Install Paper Gaskets

If you’re working with a paper gasket, there are a few things you need to keep in mind during installation. First, make sure the surface is clean and free of any debris. This will ensure a good seal.

Next, apply a thin layer of oil or grease to both sides of the gasket. This will help it slide into place more easily. Finally, align the gasket with the bolt holes and press it into place.

Use your fingers to work it around the edges so that it’s seated properly. Once everything is in place, tighten down the bolts or screws to secure the gasket. And that’s it!

You’ve successfully installed a paper gasket.

What Is A Paper Gasket?

A paper gasket is a type of seal that is used to prevent leaks in plumbing and industrial applications. Paper gaskets are made from a variety of materials, including asbestos, neoprene, and rubber. They are available in different thicknesses and sizes to suit the needs of the application.

Paper gaskets are typically used to seal joints between two flat surfaces.

A paper gasket is a thin, flat piece of material that is used to create a seal between two surfaces. Paper gaskets are commonly used in plumbing and automotive applications.

Where is a Paper Gasket Used?

A paper gasket is a type of seal that is used to fill the space between two or more mating surfaces. Paper gaskets are commonly used in plumbing and automotive applications. Paper gaskets are made from a variety of materials, including cellulose, fiberglass, and asbestos.

Asbestos paper gaskets were once very popular because they are resistant to high temperatures and chemicals. However, asbestos is now known to be a carcinogen, so it is no longer used in paper gaskets. Cellulose paper gaskets are the most common type of paper gasket.

They are made from wood pulp and other plant fibers. Cellulose paper gaskets are relatively inexpensive and easy to find. However, they are not as durable as some other types of paper gasket material.

Fiberglass paper gaskets are more durable than cellulose paper gaskets but still relatively inexpensive. Fiberglass does not break down under extreme temperatures like cellulose does, making it a good choice for applications where the temperature may fluctuate frequently or become extremely hot.

Paper gaskets can be found in many different sizes and thicknesses depending on their application. It is important to choose the right size and thickness for your application to ensure a proper seal.

What is Gasket Paper Made From?

Gasket paper is a type of material that is used to create gaskets. Gaskets are seals that are used to prevent fluids and gases from leaking. Gasket paper is made from a variety of materials, including asbestos, felt, neoprene, rubber, and cork.

What is Sheet Gasket?

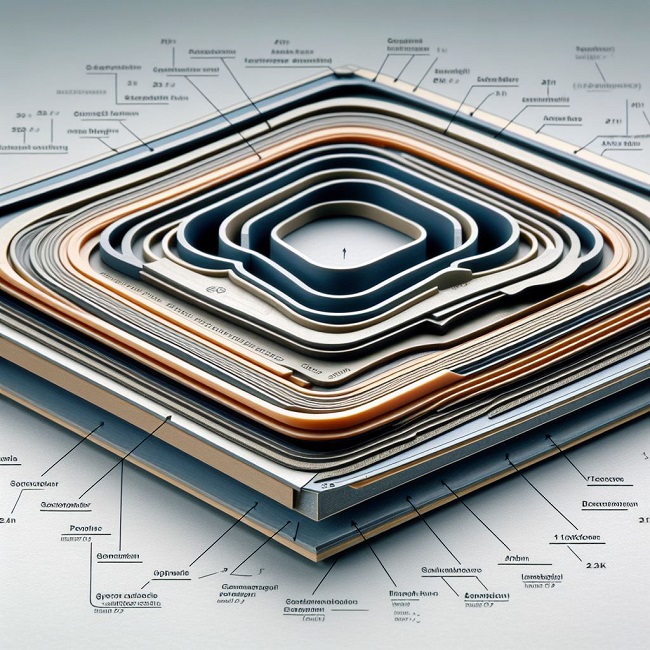

A sheet gasket is a type of gasket that is made from a flat sheet of material, usually metal or plastic. The sheet gasket is cut to fit the flange surface of two mating surfaces and then compressed between them to create a seal.

Sheet gaskets are used in many different applications, such as sealing pipe joints, valve bonnets and covers, pressure vessels, heat exchangers, and other equipment where fluids or gases are present.

There are many different types of materials that can be used to make a sheet gasket, but the most common are asbestos, graphite, PTFE (Teflon), and elastomeric materials such as nitrile rubber (NBR).

Asbestos was once the material of choice forsheet gaskets due to its high resistance to heat and chemicals, but it has been largely replaced by newer materials due to health concerns. Graphite is another popular material for sheet gaskets due to its excellent sealing properties and ability to withstand high temperatures.

PTFE is also a good option for high-temperature applications or applications where chemicals are present, as it has excellent chemical resistance. NBR is a common choice for general-purpose applications where cost is a concern, as it offers good sealing capabilities at a relatively low price.

When selecting a sheet gasket material, it is important to consider the operating conditions of the application, including temperature, pressure, media compatibility, and others.

Once the appropriate material has been selected, the next step is to select the proper thickness for the application. The thickness of the sheet gasket should be chosen so that it can compress enough to fill any irregularities on the flange surface while still being able to maintain an adequate seal under operating conditions.

If the sheet gasket is too thick or too thin for an application, it may not provide an adequate seal or may cause damage to the flanges during installation or operation.

Gasket Material

A gasket is a seal that helps to prevent fluid or gas leaks by filling the space between two surfaces. There are many different types of gaskets, but they all serve the same purpose. Gasket material is generally made from rubber, metal, or composite materials.

Metal gaskets are used in applications where there is high heat or pressure. They are also used when chemical resistance is important. Metal gaskets can be made from stainless steel, copper, aluminum, or titanium.

Rubber gaskets are commonly used in lower-pressure applications and can be made from natural rubber, neoprene, silicone, or Viton. Composite gaskets are made from multiple layers of different materials bonded together.

They offer good sealing performance and can be customized for specific applications.

Gasket Paper Thickness

When it comes to gaskets, there are a variety of materials and thicknesses that can be used. One important factor to consider when selecting a gasket is the thickness of the paper. Gasket paper thickness is typically measured in millimeters (mm).

The most common thicknesses are 0.5 mm, 1.0 mm, and 1.5 mm. There are also thicker papers available, but they are not as commonly used. The thickness of the paper will affect how well the gasket seals.

Thinner papers will compress more easily and create a tighter seal. However, they may not be as durable and could break down over time. Thicker papers will provide a less tight seal but will be more durable.

It is important to select the right thickness for your application to ensure a proper seal and long-lasting performance.

Flexoid Gasket Paper

If you’re looking for reliable and durable gasket material, look no further than flexed gasket paper. This tough, yet flexible material is perfect for sealing applications where there is a need for high temperatures or chemicals.

Made from cellulose fibers that are impregnated with special oils and resins, flexed gasket paper can withstand temperatures up to 500 degrees Fahrenheit.

It’s also resistant to most oils, greases, fuels, and solvents – making it an ideal choice for sealing automotive or industrial applications.

Gasket Paper Roll

If you’re looking for versatile, all-purpose gasket material, look no further than a gasket paper roll. This durable and easy-to-use product is perfect for a variety of applications, from sealing electrical enclosures to creating custom gaskets for unique projects.

A gasket paper roll is made of a compressed fiber sheet that has been impregnated with an elastomeric binder. This gives the material high resistance to tears and abrasion while still being flexible enough to conform to irregular surfaces.

The binder also helps the gasket material resist moisture, oils, and other common chemicals. One of the great things about gasket paper rolls is that they can be easily cut to size with scissors or a sharp knife.

This makes it ideal for creating custom gaskets on the job site or in the shop. Simply trace out the desired shape on the material and cut it out – it’s that easy! If you need a reliable, all-purpose gasketing solution, pick up some gasket paper rolls today.

It’s sure to become one of your go-to materials for a variety of applications!

Automotive Gasket Paper

An automotive gasket is a seal used to join two or more surfaces together in order to prevent leaks. Gaskets are made from a variety of materials, but the most common type is the paper gasket. Paper gaskets are usually found in engines and transmissions and are used to seal oil and coolant passages.

Paper gaskets are made from layers of compressed paper that have been impregnated with an adhesive. The thickness of the paper and the amount of adhesive used will vary depending on the application.

When choosing a paper gasket, it is important to select one that is compatible with the fluids being sealed as well as the temperature range in which the engine will be operated.

Installing a paper gasket is generally straightforward, but care must be taken to not damage the surface of the gasket or the mating surfaces. It is also important to use an even amount of pressure when tightening bolts or nuts in order to prevent leaks.

If a leak does occur, it can often be repaired by simply replacing the damaged section of gasket material.

2Mm Gasket Paper

If you’re looking for a reliable gasket material that can withstand high temperatures and pressures, look no further than 2mm gasket paper.

This tough material is made from compressed asbestos fibers and is ideal for sealing applications in a variety of industries, including automotive, aerospace, and power generation.

2mm gasket paper has excellent resistance to chemicals and oils, making it an ideal choice for sealing applications that are exposed to these substances.

It also has good abrasion resistance, meaning it can stand up to the wear and tear of constant use. This versatile gasket material can be used on both flat and curved surfaces, making it a great option for a wide range of applications.

And because it’s so thin (just 2mm!), it’s easy to work with and can be cut to size with regular scissors. If you’re looking for a high-quality gasket material that can handle even the most demanding applications, 2mm gasket paper is the way to go!

1Mm Gasket Paper

If you are in need of a gasket for your next project, consider using 1mm gasket paper. This type of gasket is ideal for use in a variety of applications and can be easily cut to size with a sharp knife or scissors.

Here are some additional facts about 1mm gasket paper that you may find helpful:

- Gasket paper is available in a variety of thicknesses, but 1mm is a good all-purpose choice.

- This type of gasket material is easy to work with and can be glued or taped into place.

- 1mm gasket paper provides excellent sealing properties and can withstand high temperatures.

- This product is also resistant to oils, solvents, and other chemicals.

- Gaskets made from 1mm gasket paper are often used in automotive and industrial applications.

Whether you’re looking for an inexpensive way to seal a leaky pipe or you need a durable gasket for a high-performance engine, 1mm gasket paper may be the perfect solution for your needs.

Grease on Paper Gaskets

If you’re using paper gaskets, you need to apply a thin layer of grease to both sides of the gasket. This will help the gasket seal properly and prevent leaks. There are a few different types of greases that can be used for this purpose.

Silicone grease is a good option because it’s compatible with most materials and it won’t harden or deteriorate over time. You can also use petroleum jelly or engine oil. Whichever type of grease you choose, make sure to spread it evenly over the surface of the gasket.

Too much grease can cause leaks, so don’t go overboard! Once you’ve applied the grease, install the gasket and tighten everything down according to your vehicle’s specifications.

Should You Use Rtv With a Paper Gasket

If you’re wondering whether or not you should use RTV with a paper gasket, the answer is yes! Here’s why: RTV stands for room-temperature vulcanizing silicone, which is a type of sealant that cures at room temperature.

It’s ideal for sealing paper gaskets because it creates a watertight and airtight seal that won’t leak. Plus, it’s easy to apply and doesn’t require any special tools or equipment.

When used correctly, RTV can provide a reliable seal that will last the life of the engine. However, there are some important things to keep in mind when using RTV with paper gaskets.

First, it’s important to choose the right type of RTV for the application. There are two main types of RTV silicone: acetic cure and neutral cure. Acetic cure RTV is activated by exposure to air, while neutral cure RTV is activated by exposure to moisture.

For paper gaskets, it’s best to use neutral cure RTV to prevent corrosion. Second, pay attention to how much RTV you’re using. Too much RTV can squeeze out from under the gasket and cause leaks.

Conversely, not enough RTV can allow the gasket to shift and create gaps that allow oil or coolant to leak through. The best way to apply RTV is to dispense a small bead onto one side of the gasket and then spread it evenly with your finger before installing the gasket onto the engine block or cylinder head.

Finally, give the sealant time to cure properly before starting up your engine. Most brands of neutral cure RTV recommend allowing 24 hours for the sealant to fully cured before putting any pressure on it (such as starting up your engine).

Permatex on Paper Gasket

If you’re looking for a reliable product to use when creating paper gaskets, Permatex is a great option. This sealing compound is designed for use with non-asbestos materials and can withstand high temperatures. It’s also oil and grease-resistant, making it ideal for automotive applications.

Here’s a closer look at how to use Permatex on paper gaskets: To begin, clean the surface of the flange where the gasket will be placed. Next, apply a thin layer of Permatex to one side of the gasket.

Be sure to avoid getting any on the bolt holes. Now place the gasket onto the flange, being careful not to move it around too much so that the Permatex doesn’t become displaced.

Tighten down the bolts or screws that will hold the gasket in place, then check that there are no leaks by doing a pressure test on the system. If everything looks good, you’re all set! Thanks to Permatex, your paper gasket should provide a solid seal that will last for years to come.

Do Rubber Gaskets Need Sealant

If you’re like most people, you probably don’t think much about the humble rubber gasket. But these little seals play an important role in many mechanical applications, such as keeping water and other fluids out of car engines.

In fact, just about any time two surfaces need to be sealed together, there’s a good chance a rubber gasket is involved.

But do rubber gaskets need sealant? The answer is: it depends. There are many different types of rubber gaskets, and each has its own unique properties and requirements.

In general, however, most rubber gaskets can benefit from the use of a sealant. A sealant helps to fill in any tiny gaps or imperfections in the surface of the gasket, creating a tighter seal that is less likely to leak. It also helps to protect the gasket from degradation due to chemicals or other environmental factors.

And in some cases, a sealant can even increase the lifespan of a gasket by helping it withstand higher temperatures or pressures. So if you’re wondering whether or not to use a sealant on your next project involving rubber gaskets, the answer is probably yes!

Just be sure to select the right type of sealant for the particular application and follow all manufacturers’ instructions carefully.

Read More: Can I Fillin Over Sealant Foam If Necessary

Best Paper Gasket Sealer

Are you looking for a sealer that will create a reliable and durable seal for your paper gaskets? If so, then you need to use the best paper gasket sealer on the market.

This guide will teach you everything you need to know about selecting and using the best paper gasket sealers so that you can make an informed decision about which product is right for your needs.

What Is a Paper Gasket Sealer? A paper gasket sealer is a type of adhesive that is specifically designed to bond paper gaskets to metal surfaces. This type of glue creates a strong bond between the two materials, which prevents leaks and ensures that the gasket stays in place.

Paper gasket sealers are available in both water-based and solvent-based formulas, so you can choose the option that best suits your needs. How to Select the Best Paper Gasket Sealer When choosing a paper gasket sealer, it is important to consider the specific application in which it will be used.

For example, if you are sealing a paper gasket that will be exposed to high temperatures, then you need to choose a sealer with high heat resistance. Similarly, if you are working with an oil-based engine, then you need to select an oil-resistant paper gasket sealer.

Other factors such as cure time, strength, and flexibility should also be considered when making your selection. Once you have determined the specific requirements for your project, it is time to start shopping around for the best paper gasket sealer.

There are many products on the market, so take some time to read reviews from other customers before making your final decision. You can also ask for recommendations from friends or family members who have experience with this type of product.

Once you have selected the perfect product for your needs, follow the instructions on the package carefully in order to ensure optimal results.

Loctite 518 With Paper Gasket

Loctite 518 is a high-strength anaerobic sealant that bonds and seals metal fittings. It is designed for use with paper gaskets and can be used on a variety of surfaces, including aluminum, stainless steel, and cast iron. Loctite 518 provides a strong, permanent bond that resists vibration and thermal cycling.

It can be used in temperatures ranging from -65°F to 300°F (-54°C to 149°C).

Paper Gasket Install Dry

If you’re installing a paper gasket, the first thing you need to do is dry it out. This will help to prevent any leaks. Next, you need to apply some adhesive to both sides of the gasket.

Then, you can install it onto the surface that you’re sealing. Make sure that you press it down firmly so that it makes good contact with the surface. Once it’s in place, you can add whatever else you need to complete your seal.

How to make a paper gasket for almost anything super cheap!

Conclusion

No, paper gaskets do not need sealant. Paper gaskets are made of compressed paper fibers and are coated with a sealing material such as silicone or rubber.

![Can I Use Foam Sealant For Gaps In Shower Fixtures [Proper Guide]](https://glueanswer.com/wp-content/uploads/2024/01/Can-I-Use-Foam-Sealant-For-Gaps-In-Shower-Fixtures-Proper-Guide-768x432.jpg)