3M VHB vs Gorilla Tape: In-Depth Comparison and Review

3M VHB vs. Gorilla Tape: Compare the Strengths, Applications, and Distinctive Features of Two Premier Adhesive Solutions.

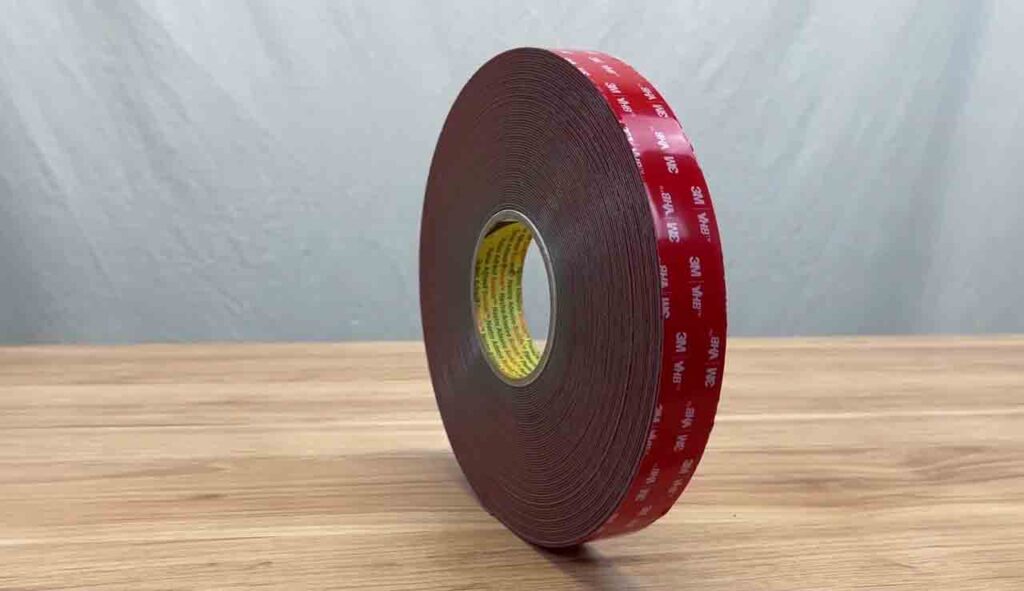

3M VHB tape is a versatile industrial solution designed to withstand extreme conditions such as heat, weather fluctuations, cold, and UV exposure. Its robust construction makes it an ideal choice for a wide range of industrial applications, where durability and long-lasting bonding are paramount.

On the other hand, Gorilla Tape, known for its strength and versatility, finds its place in both indoor and outdoor settings. Suitable for use on diverse surfaces, including wood, glass, brick, ceramic, stone, and some plastics, Gorilla Tape is a reliable adhesive for general household needs. However, it is important to note that Gorilla Tape is not primarily designed for permanent bonding.

Today we will discuss more about 3m VHB vs gorilla.

3m VHB Vs Gorilla Mounting Tape: Quick Comparison

Here’s a quick side-by-side comparison of 3M VHB and Gorilla adhesive tape:

| Property | 3M VHB | Gorilla |

| Temperature Range | 70°F to 100°F | 200°F to 220°F |

| Bonding Time | 72 hours | 24 hours |

| Shelf Life | 24 months | 2 years |

| Thickness | 0.045 inch | 0.4 – 2.0 mm |

| Peel Strength | 22 lb/in | 30 PSI |

Choosing the right double-sided tape for your project can be tricky, especially when faced with popular options like Gorilla Tape and 3M VHB. Both offer strong bonds, but they differ in key features that might make one a better fit than the other for your specific needs.

| Feature | Gorilla Tape | 3M VHB |

| Type of tape | Reinforced polyethylene | Acrylic foam |

Check Price |  Check Price | |

| Strength | Moderate strength, up to 30 pounds per square inch | Strong, up to 1,100 pounds per square inch |

| Adhesion | Good on many materials, but struggles with low surface energy plastics | Excellent on a wide range of materials, including metals, plastics, wood, and glass |

| Temperature resistance | Up to 180°F (82°C) | Up to 200°F (93°C) |

| Weather resistance | Good, but may degrade over time in harsh weather conditions | Excellent, holds up well to sunlight, rain, and snow |

| Removable | Not easily removable, can tear surfaces upon removal | Some variants are removable, but may leave residue |

| Transparency | Mostly clear, but with a slightly visible grid pattern | Available in both clear and colored options |

| Cost | Less expensive | More expensive |

| Best for | Lighter-duty applications, temporary bonding, applications where cost is a major factor | Heavy-duty applications, permanent bonding, applications requiring high bond strength and temperature resistance |

1. Gorilla Tape

2. 3M VHB

Additional Notes:

- 3M VHB is generally considered the superior tape due to its stronger adhesion, wider range of compatible materials, and better weather resistance. However, Gorilla Tape is a more affordable option for light-duty applications where its slightly lower bond strength won’t be an issue.

- Both tapes offer waterproof options, making them suitable for outdoor use.

- Always follow the manufacturer’s instructions for application and removal to ensure optimal performance.

What Is Gorilla Tape Used For?

- Heavy-Duty Repairs: Ideal for fixing and patching various surfaces.

- Indoor and Outdoor Use: Versatile for both interior and exterior applications.

- Tough and Rugged: Designed to handle rough and demanding tasks.

- Multipurpose: Suitable for a wide range of materials, such as wood, metal, plastic, and more.

- Temporary Fixes: Offers a quick and reliable solution for emergency repairs.

Types Of Gorilla Tape

- Gorilla Tape: All-purpose, strong and durable adhesive tape.

- Crystal Clear Gorilla Tape: Transparent tape for discreet repairs.

- Camo Gorilla Tape: Blends with outdoor surroundings for camouflage.

- Heavy Duty Mounting Tape: Strong adhesive for mounting applications.

- Tough & Clear Mounting Tape: Transparent and durable mounting tape.

- Packaging Tape: Designed for secure and reliable packaging applications.

Is Gorilla Tape Safe To Use?

Gorilla Tape is generally safe to use. However, prolonged skin contact may irritate. It’s recommended to avoid direct contact with the adhesive and to test a small area first.

How Strong Is Permanent Gorilla Tape?

Gorilla Tape is known for its strength, boasting an impressive 85 lb resistance before breaking. This adhesive tape is designed to be durable and robust.

Why Is Gorilla Tape So Strong?

Gorilla Tape is exceptionally strong due to its durable construction. It incorporates a reinforced backing with a strong adhesive layer, making it resistant to extreme temperatures, UV rays, and moisture. The combination of these features results in a tape that offers superior strength and adhesion.

Why Is Gorilla Tape So Sticky?

Gorilla Tape’s exceptional strength lies in its composition, featuring a highly concentrated rubber adhesive. This robust adhesive ensures superior bonding on a variety of surfaces, making Gorilla Tape an unparalleled choice for durable and resilient adhesion in various applications.

How Long Can Gorilla Tape Last?

Gorilla Tape is designed for durability, with a strong adhesive that can withstand extreme conditions. While its lifespan depends on usage and environmental factors, it typically lasts for years, making it a reliable choice for various applications.

Is Gorilla Glue Heat Safe?

Yes, Gorilla Glue is heat-resistant, making it suitable for a variety of applications. Its robust formula ensures durability even in high-temperature environments.

Does Lemon Juice Remove Gorilla Glue?

While lemon juice is a common household item with various uses, it effectively removes Gorilla Glue.

How Do You Store Gorilla Tape?

To ensure your Gorilla Tape remains ready for action, store it in a cool, dry place away from direct sunlight. Seal the roll tightly after use to prevent drying out. Keep your tape primed for any sticky situation!

How Do You Apply Gorilla Tape?

Read More About Choosing the 3 Best Mastic Duct Sealant: A Comprehensive Guide

Step 1: Surface Prep

Before you unleash the power of Gorilla Tape, ensure the surface is clean and dry.

Step 2: Measure and Cut

Like a precision surgeon, measure the tape length you need and cut it with a sharp pair of scissors or a utility knife. Gorilla Tape is forgiving, but let’s not test its patience with jagged edges.

Step 3: Peel and Stick

Ah, the satisfying moment – peeling the backing off. Do it slowly to avoid any accidental acrobatics. Now, press the tape firmly onto the surface, starting from one end and working your way to the other.

Step 4: Seal the Deal

Give it an extra dose of adhesion by firmly pressing along the entire length of the tape. Your fingers might get a bit of a workout, but it’s worth it for that unbeatable bond.

Step 5: The Waiting Game

Let it sit and bond for at least a few minutes – patience is a virtue. For heavy-duty applications, allow it to reach its full strength over the next 24 hours.

Tips and Tricks

Temperature Matters

Gorilla Tape thrives in a Goldilocks environment. Too cold, and it might not stick as well; too hot, and it might get overly sticky. Aim for a moderate temperature for optimal results.

Overlap for Strength

When dealing with heavy loads or high-stress areas, consider overlapping the tape to reinforce the bond. It’s like giving your project a superhero cape.

How Do You Remove Gorilla Glue?

While Gorilla Glue is known for its strength, there are a few methods you can try to loosen its grip:

Soap and Water

- Start with a mixture of warm water and soap.

- Gently scrub the affected area with a cloth or sponge.

- This method works well for fresh glue spills, but for hardened glue, you might need to try something stronger.

Acetone

- Acetone is a powerful solvent that can break down Gorilla Glue.

- Dampen a cloth with acetone and apply it to the glued surface.

- Let it sit for a few minutes to allow the acetone to work its magic.

- Gently rub or scrape off the glue with a plastic scraper or your fingers.

Lemon

- The natural acidity of lemon can help soften the glue.

- Squeeze fresh lemon juice onto the glued area.

- Allow it to sit for a while to penetrate the glue.

- Use a soft cloth or sponge to wipe away the glue residue.

What Does 3m VHB Stand For?

Developed by the renowned 3M company, the VHB series has become a game-changer in the realm of bonding solutions. 3M VHB stands for “Very High Bond,”.

Now, let’s break down the acronym:

- V – Very: Emphasizing an exceptional level of bonding capability, surpassing ordinary adhesives.

- H – High: Signifying a superior degree of strength, resilience, and durability.

- B – Bond: Highlighting its primary function – creating robust bonds between various surfaces.

What is VHB tape used for?

- VHB (Very High Bond) tape is a versatile adhesive solution designed for bonding a wide range of materials.

- It excels in applications where a strong, durable, and virtually invisible bond is required.

- Commonly used in the automotive, construction, and electronics industries.

- Offers excellent resistance to temperature, chemicals, and UV, ensuring long-lasting performance.

- Ideal for replacing traditional fasteners, creating a clean and streamlined appearance in various projects.

Read Also HVAC Tape vs Duct Tape: Key Differences and Best Uses

Advantages Of 3m VHB Tape

- Ultimate Bonding: 3M VHB tape ensures a powerful and durable bond, replacing traditional fasteners.

- Versatility: Ideal for various surfaces, including metals, plastics, and painted surfaces.

- Shock Absorption: Offers excellent resistance to dynamic loads and vibrations.

- Weather Resistance: Withstands extreme temperatures, UV rays, and harsh weather conditions.

- Time Efficiency: Eliminates the need for drilling or additional processes, saving time and labor costs.

- Clean Aesthetics: Creates a seamless, aesthetically pleasing finish for a polished look.

How Much Weight Can 3m VHB Tape Hold?

The 3M VHB Tape has a reputation for its robust bonding capabilities, and it’s no slouch in the weight department. In fact, this tape can handle a substantial load, and your estimate of 45 pounds is right on the money.

How Long Does 3m VHB Tape Last?

The recommended shelf life is typically around 24 months. However, it’s important to note that this is a general guideline and not an absolute guarantee.

Can 3m VHB Tape Replace A Fastener?

Absolutely! This innovative tape is a game-changer in the world of fastening. It’s designed to replace screws, bolts, and other mechanical fasteners, providing a durable bond.

What makes 3M VHB Tape stand out is its ability to create a bond that is not only robust but also aesthetically pleasing. No more visible screws or bolts disrupting the smooth surface – the tape offers a clean and seamless appearance.

Will 3m VHB Damage Paint?

Rest assured, the 3M VHB (Very High Bond) tape is designed to provide strong adhesion without causing damage to paint surfaces. Its adhesive properties are effective yet gentle, ensuring a secure bond without leaving behind any unsightly marks. Your paint job is in safe hands with 3M VHB!

Does 3m VHB Stick To Plastic?

Absolutely! 3M VHB (Very High Bond) tape is designed to adhere securely to a variety of surfaces, including plastics. Its strong bond and durability make it an excellent choice for various applications. Trust 3M VHB for reliable and long-lasting adhesion on your plastic surfaces.

Why Is 3m Tape So Strong?

3M tape is engineered with advanced adhesive technology and high-quality materials, resulting in exceptional strength. Its durability and bonding capabilities make it a reliable choice for various applications, ensuring lasting performance.

Does VHB Stick To Brick?

Absolutely! VHB (Very High Bond) tape adheres exceptionally well to brick surfaces. Its robust bonding strength ensures a secure and durable connection. Trust VHB for reliable performance in your brick applications.

Does 3m VHB Stick To Glass?

Yes! 3M VHB is an excellent choice for bonding with glass. Its advanced adhesive technology ensures a strong and durable connection. Trust in the reliability of 3M VHB for your glass bonding needs.

What Surfaces Are The Worst To Apply 3m VHB Tape On?

When it comes to applying 3M VHB tape, rough, porous, or fibered surfaces can pose challenges. These textures may compromise the tape’s optimal adhesion. Smooth, clean surfaces are ideal for maximizing the effectiveness of 3M VHB tape.

How Does Gorilla Tape Stack Up Against 3m VHB?

Gorilla Tape and 3M VHB are both heavyweights in the adhesive game, but they bring different strengths to the ring. Gorilla Tape flexes its muscles with exceptional toughness and versatility, ideal for quick fixes.

On the other hand, 3M VHB showcases its finesse, providing a robust, long-term bonding solution. The choice depends on your project’s needs – whether you’re looking for a quick patch-up or a lasting commitment.

3m VHB Tape Strength Test

UV Test

3M VHB Tape stands the test of time under the sun’s harsh rays. UV-resistant, it maintains its integrity, providing long-lasting performance.

Temperature Test

From scorching heat to freezing cold, 3M VHB Tape remains unwavering. Its resilience ensures a steadfast bond across a wide temperature range.

Water Resistant Test

Dive into confidence with 3M VHB Tape—water-resistant and dependable. It withstands moisture challenges, maintaining adhesion in various environments.

3m VHB Tape Selection Guide

We’ve crafted this Selection Guide to be your compass in the adhesive landscape:

1. Understanding Your Project

Before diving into the tape selection process, take a moment to assess your project’s specific requirements. This initial step sets the stage for a successful tape pairing.

2. VHB Tape Families

Our VHB Tapes come in various families, each designed to address specific challenges. Whether you’re dealing with metals, plastics, or high-energy surfaces, there’s a VHB Tape tailored to meet your demands.

- General-Purpose Tapes: Perfect for everyday applications, these tapes provide reliable bonding strength across a range of surfaces.

- High-Temperature Tapes: For projects exposed to extreme heat, opt for our high-temperature-resistant tapes. Specialty Tapes: When unique challenges arise, our specialty tapes step in. From conformable tapes for irregular surfaces to low-surface-energy bonding solutions.

3. Thickness Matters

Selecting the right tape thickness is crucial. Thicker tapes offer increased strength and durability, making them ideal for heavy-duty applications. On the other hand, thinner tapes excel in applications where flexibility and conformability are paramount.

3M VHB vs Alien Tape

3M VHB and Alien Tape are adhesive solutions with distinct features. 3M VHB offers a temperature range of 70°F to 100°F, requiring 72 hours for full bonding, with a 24-month lifespan.

| Feature | 3M VHB | Alien Tape |

| Temperature Range | 70°F to 100°F | Up to 200°F |

| Bonding Time | 72 hours for full bonding | Instant bonding |

| Lifespan | 24 months | 6 months to 2 years |

| Thickness | 0.045 inches | 2.0 mm |

| Bonding Strength | 22 lb/in | Supports weights up to 17.5 lb |

Fig: This chart summarizes the key features of 3M VHB and Alien Tape, making it easier to compare their characteristics.

It boasts a thickness of 0.045 inches and a strong 22 lb/in bonding strength. In contrast, Alien Tape accommodates temperatures up to 200°F, providing instant bonding and lasting 6 months to 2 years. It has a thicker profile at 2.0 mm and supports weights up to 17.5 pounds.

How to Store 3M VHB

To ensure optimal performance of your 3M VHB (Very High Bond) tape, store it in a cool, dry place away from direct sunlight. Keep the rolls or sheets in their original packaging to protect them from dust and contaminants. Remember, a well-preserved tape is a strong bond!

3m VHB Tape Application Guide

Here is a general application guide for 3M VHB tape:

1. Surface Preparation

Clean the surfaces with a mild solvent such as isopropyl alcohol. Allow the surfaces to dry completely before applying the tape.

2. Temperature Considerations

Avoid applying the tape in extremely hot or cold temperatures, as it may affect the bonding performance.

3. Tape Selection

Choose the appropriate 3M VHB tape based on the application requirements, such as the type of materials being bonded and the weight or stress on the bond.

4. Cutting the Tape

Use sharp scissors or a knife to cut the tape to the desired length. 3M VHB tape is often available in rolls or pre-cut pieces.

5. Application

Peel off one side of the liner to expose the adhesive surface. Align the tape on one of the substrates and press it firmly into place.

6. Bonding Pressure

Apply sufficient pressure to ensure good contact between the tape and the substrates. This can be achieved using your hands, a roller, or another suitable tool.

7. Cure Time

While 3M VHB tape provides instant bonding, optimal performance is achieved after allowing the bond to cure for 72 hours.

How Do I Remove 3m VHB Tape From A Surface?

To remove 3M VHB tape from a surface, follow these steps:

- Heat: Use a hair dryer or heat gun to warm the tape, making it more pliable.

- Peel: Carefully peel off the tape from one corner, pulling it parallel to the surface.

- Adhesive Remover: Apply a commercial adhesive remover or rubbing alcohol to any remaining adhesive.

- Scrub: Use a soft cloth or sponge to scrub away the adhesive.

- Clean: Wipe the surface with a clean, damp cloth to remove any residue.

Is Gorilla Or 3m Tape Better?

When it comes to choosing between Gorilla Tape and 3M Tape, both are reputable brands, each with its strengths. Gorilla Tape is known for its exceptional strength and durability, ideal for heavy-duty applications.

On the other hand, 3M Tape is praised for its versatility and adhesive technology. Consider your specific needs, whether it’s robust bonding or multi-surface adhesion, to determine which type suits your project best.

FAQs

What is an alternative to 3M VHB?

An alternative to 3M VHB is Gorilla Heavy-Duty Mounting Tape, offering strong adhesive properties for secure and durable bonding applications.

Can You Laser VHB Tape?

Yes, VHB Tapes can be laser cut using a 10.6 micron laser. The process is effective for precision cutting.

How Thick Is 3m VHB?

The thickness of 3M VHB (Very High Bond) tape is typically 0.045 inches, equivalent to 1.143 millimeters.

Is there tape stronger than Gorilla Tape?

There are tapes claiming to be stronger than Gorilla Tape, such as T-Rex Tape and FiberFix, but opinions may vary.

Is Gorilla Tape 3 times stronger?

Gorilla Tape is advertised as being three times stronger than conventional duct tape, providing enhanced durability for various applications.

Conclusion

Both 3M VHB vs Gorilla tapes are reputable brands known for their strong bonding capabilities. The choice between the two ultimately depends on specific project requirements, with both brands offering reliable solutions for different applications.