Which 3M VHB Tape Is The Strongest: Expert’s Selection Guide

How can two items be connected to ensure resistance to extreme temperatures, water damage, UV light, and solvents? You need the strongest 3m tape for this kind of situation.

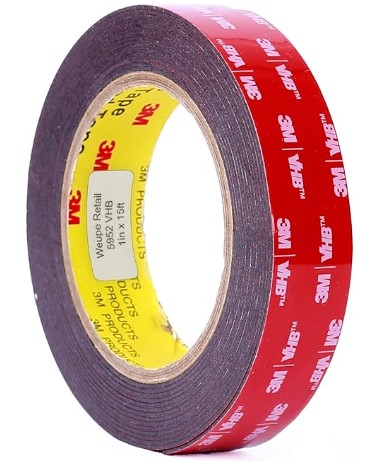

Which 3m VHB tape is the strongest? 5952 VHB Tape, Double Sided, and HitLights Mounting Foam Tape are the strongest.

Choosing the Strongest:

- 3M VHB Tape 5952: Strongest for its weight (90 lbs/inch), good for general bonding and temperature resistance.

- Double Sided Heavy Duty 3M VHB Tape: Excellent industrial strength, versatile, weatherproof, and discreet bonding option.

- Heavy Duty 3M VHB Tape: Exceptional overall bonding strength, ideal for demanding applications across various materials.

Let’s discuss why these 3 tapes are the strongest.

Here’s a comparison table of three popular choices:

| Feature | 3M VHB Tape 5952 | Double Sided Heavy Duty 3M VHB Tape | Heavy Duty 3M VHB Tape |

| Product | Check Price | ||

| Bonding Strength | 90 lbs per inch | High-strength industrial adhesive | Exceptional bonding strength |

| Thickness | 0.045 inches | Varies | Varies |

| Temperature Resistance | Up to 250°F | Varies | Varies |

| Material Compatibility | Versatile (metals, plastics, composites) | Very versatile (metals, plastics, composites, glass) | Versatile (metal, glass, plastic, painted surfaces) |

| Ease of Use | Straightforward, but repositioning can be difficult due to strong adhesion. | Easy to handle, cut, and apply. | Comes in roll form for easy application and customization. |

| Appearance | High-profile (visible tape) | Double-sided option for discreet bonding. | Clear option available for a visually clean aesthetic. |

| Applications | General bonding, signage, automotive, construction | Industrial-strength applications, construction, manufacturing, signage | Various demanding applications across industries |

| Pros | Strong adhesion, temperature resistance, durable, consistent performance | Industrial strength, double-sided, versatile, weather resistant, clean aesthetic | Exceptional bonding strength, weather resistant, no visible fasteners, quick application |

| Cons | Repositioning can be challenging, high-profile | Strong bond may make removal difficult | Surface preparation required |

Which 3M VHB Tape Is The Strongest?

The choice of the strongest tape depends on factors such as the materials being bonded and the surface conditions. Some of the commonly used and strong 3M VHB tapes include:

1. 5952 VHB Tape

The 5952 VHB Tape is a high-performance, double-coated adhesive tape designed for a wide range of applications. Its exceptional bonding strength of 90 pounds makes it a versatile solution for joining different materials securely.

Key Features

Double-Coated Design: The tape features a double-coated structure, providing superior adhesion and bonding strength.

Thickness: With a thickness of 45 mils, the tape offers durability and resilience, making it suitable for demanding applications.

High Temperature Resistance: Capable of withstanding temperatures up to 250°F, ensuring stable performance in hot environments.

Strong Bonding: Boasting an impressive 90-pound bonding strength, the tape securely fastens materials, contributing to the overall structural integrity.

Reliable Performance: The 5952 VHB Tape delivers consistent and reliable performance, meeting the demands of challenging applications.

Pros

- Strong Adhesion

- Temperature Resistance

- Suitable for bonding different materials

- Durable Construction

- Consistent Performance

Cons

- Proper application may require attention to detail, as the tape’s strong adhesion could make repositioning challenging.

2. Double Sided Heavy Duty 3M VHB Tape

Whether you’re working on construction projects, signage, automotive applications, or other demanding scenarios, this tape is engineered to provide exceptional holding power.

Key Features

Industrial Strength: The tape is backed by 3M’s VHB technology, ensuring a high-strength bond that can withstand extreme conditions, including temperature variations, moisture, and UV exposure.

Double-Sided: Featuring adhesive on both sides, this tape creates a robust connection between surfaces, enhancing stability and preventing separation.

Versatility: Suitable for a wide range of materials, including metals, plastics, and composites, making it an ideal choice for various applications in construction, manufacturing, and more.

Ease of Use: The tape is easy to handle, cut, and apply, simplifying the installation process and saving time on projects.

Weather Resistant: Resistant to harsh weather conditions, the tape maintains its adhesive strength even in extreme temperatures, making it suitable for both indoor and outdoor applications.

Transparent Option: Some variants of the tape are available in a transparent finish, providing a discreet and clean look after application.

Pros

- High Bond Strength

- Versatile Application

- Time-Efficient

- Weather Resistance

- Clean Aesthetic

Cons

- While the strength of the bond is a pro, it can be a con if removal or repositioning is necessary, as it may damage surfaces.

3. Heavy Duty 3M VHB Tape

The Heavy Duty 3M VHB Tape is an industrial-strength adhesive solution designed to provide a reliable and long-lasting bond between various surfaces. Whether you’re in the automotive, construction, or manufacturing industry, this tape offers a secure and efficient way to join materials.

Key Features

Exceptional Bonding Strength: The 3M VHB Tape is renowned for its extraordinary bonding strength, creating a permanent seal between surfaces.

Versatility: Suitable for various materials, including metal, glass, plastic, and painted surfaces, making it a versatile solution for different applications.

Weather Resistance: Resistant to extreme weather conditions, UV rays, and temperature fluctuations, ensuring a reliable bond even in challenging environments.

Ease of Use: The tape comes in roll form, allowing for easy application and customization to fit specific project requirements.

Clear and Aesthetic Bonding: With a clear appearance, the tape provides a visually clean and aesthetically pleasing bond without the need for unsightly fasteners.

Pros

- Industrial Strength

- No Visible Fasteners

- Quick Application

- Durable in Harsh Environments

Cons

- Surface Preparation Required

Advantages Of 3m VHB Tape

- Ease of Use: 3M VHB (Very High Bond) Tape is user-friendly, offering a straightforward application process without the mess associated with dripping glue.

- No Drying Time: Unlike traditional adhesives, VHB Tape doesn’t require drying time, allowing for immediate bonding.

- High Strength: Known for its exceptional bonding strength, VHB Tape provides a robust and durable hold for various materials and applications.

- Thermal Expansion Adjustment: The tape accommodates thermal expansion and contraction, maintaining its bond integrity across temperature fluctuations.

- Solvent Resistance: VHB Tape resists the damaging effects of solvents, ensuring longevity and reliability in challenging environments.

- The elastic properties of VHB endure within the temperature range of -40°C to 90°C.

Read More About 3M VHB vs Gorilla Tape: In-Depth Comparison and Review

3m VHB Tape Difference

Various 3M VHB tapes cater to diverse industries, such as automotive and commercial vehicles. Tailored for specific applications, these tapes excel in high/low temperatures, waterproofing, or weatherproofing. Some provide rapid strength, while others progressively strengthen over 72 hours.

Which VHB Tapes Work Best?

3M VHB tapes are renowned for their strong bonding performance in various applications. Their durability and versatility make them suitable for bonding metals, plastics, and other materials securely.

Are All 3m VHB Tapes The Same?

No, not all 3M VHB (Very High Bond) tapes are the same. 3M offers a variety of VHB tapes with different formulations designed for specific applications, such as bonding metals, plastics, or high-temperature resistance.

It’s crucial to choose the appropriate VHB tape based on the intended use for optimal performance.

How Much Weight Can 3m VHB Tape Hold?

3M VHB tape is renowned for its strength. It can securely hold over 45 pounds of weight, providing reliable bonding for various applications, from mounting to industrial uses.

How Long Does 3m VHB Tape Last?

3M VHB tape typically lasts for up to 24 months, providing a strong and durable bond. Its longevity is influenced by factors such as application conditions and environmental factors.

Does 3m VHB Tape Damage Walls?

3M VHB Tape is designed to adhere strongly to various surfaces without causing damage. However, improper removal or application on delicate surfaces may result in damage. Always follow the manufacturer’s guidelines for proper usage to ensure optimal performance and surface protection.

Can 3m VHB Tape Replace A Fastener?

3M VHB Tapes boast numerous features and advantages compared to mechanical fasteners:

- Streamlined assembly process, enhancing efficiency and simplifying overall assembly.

- Enhanced design aesthetics, allowing for product assembly without visible holes or mechanical fasteners.

- Virtually imperceptible fastening for a smooth surface appearance.

- Substitutable for mechanical fasteners or liquid adhesives.

- Provides robust strength and long-lasting durability.

- Resistant to environmental elements like water damage, UV light effects, and temperature extremes.

- Flexible and capable of bending around objects that aren’t perfectly flat.

- Reduces preparation work and finishing, as opposed to many mechanical fasteners that necessitate grinding, drilling, or post-refinishing.

- Customizable to precise shapes and sizes to seamlessly integrate into the design3.

Will 3m VHB Damage Paint?

3M VHB (Very High Bond) tape is designed not to damage paint when properly applied and removed. Its adhesive strength allows for secure bonding without harming surfaces.

Is VHB Tape Waterproof?

Yes, VHB (Very High Bond) tape is generally waterproof. It is designed to provide a strong and durable bond even in challenging conditions, including exposure to water. VHB tape is commonly used in various industries for its reliability.

Does 3m VHB Stick To Plastic?

Yes, 3M VHB (Very High Bond) tape is designed to adhere strongly to a variety of surfaces, including many types of plastics. Its high-performance acrylic adhesive provides durable and long-lasting bonds, making it a reliable choice for plastic-to-plastic or plastic-to-other-material applications.

Is Gorilla Or 3m Tape Better?

Both Gorilla Tape and 3M Tape are reputable brands known for their strong adhesion. The choice depends on specific needs; Gorilla Tape is durable and weather-resistant, while 3M offers a range of specialized tapes for different applications.

Why Is 3m Tape So Strong?

3M tapes are strong due to advanced adhesive technology. They use acrylic adhesives that provide excellent bonding strength. Additionally, the tapes are designed for specific applications, ensuring optimal performance.

The combination of innovative materials and precise engineering contributes to their strength and durability.

Does 3m VHB Stick To Glass?

Yes, 3M VHB (Very High Bond) tape is designed to adhere strongly to various surfaces, including glass. Its high-performance acrylic adhesive provides durable and long-lasting bonding, making it suitable for a wide range of applications on glass surfaces.

Does VHB Stick To Brick?

Yes, VHB tape is designed to adhere strongly to brick. Its high-strength adhesive provides durable bonding, making it suitable for various applications.

What Does 3m VHB Stand For?

3M VHB stands for “3M Very High Bond.” It is a type of adhesive tape produced by 3M that offers strong and durable bonding capabilities. VHB tapes are widely used in various industries for applications requiring reliable and long-lasting adhesion.

What Surfaces Are The Worst To Apply 3m VHB Tape On?

3M VHB Tape adheres poorly to fibered, rough, and porous surfaces. The tape’s effectiveness diminishes on such substrates, hindering its ability to form a strong bond. For optimal performance, it’s recommended to apply 3M VHB Tape on smooth, clean, and non-porous surfaces.

How Does Gorilla Tape Stack Up Against 3m VHB?

Gorilla Tape and 3M VHB serve different purposes. Gorilla Tape is a heavy-duty adhesive tape for quick fixes, while 3M VHB is a high-strength bonding tape designed for permanent applications. Choose based on your specific needs.

3m VHB Tape Strength Test

- Outdoor Weather Test

3M utilizes outdoor weathering decks in Florida to assess tape bond performance in hot, moist, UV-intensive conditions. Similar tests in Arizona demonstrate 100% bond strength retention over 2-5 years.

- Vibration and Fatigue Testing

A semi-truck with a sleeper cab, constructed using 3M’s VHB tape, outperformed welded parts in a 500,000 km durability test. Tape bonds remained intact, surpassing some mechanical connections.

- Moisture and Solvent Testing

3M VHB tape is a reliable moisture seal and corrosion inhibitor for dissimilar metals, demonstrated in splash tests with chemicals, water, oils, petrol, and 10-year saltwater submersion.

- Temperature Testing

3M VHB recommended application temperature is 20ºC – 40ºC. Specific types may have distinct specifications determined by testing and material composition for optimal performance.

3m VHB Tape Selection Guide

Here’s a general guide to help you select the right 3M VHB tape:

- Selecting the Appropriate Tape for Specific Tasks

Choose VHB tapes like 4941, 5952, 4991, 4945, 5925, or 5962 for paint/plastic bonding. Opt for 4618, 4624, or 4622 for dissimilar materials; 4941/4991 for textured surfaces. Use 4991, 4941, or 4945 for flexible vinyl; 4618, 4622, or 4624 for unlike materials.

- Making Adhesive Properties a Key Factor in Your Choice

Select a tape based on its adherence to specific materials. 3M VHB tapes bond effectively to glass, metals, and high surface energy plastics without priming. Abrasion may enhance adhesion on certain surfaces.

- Factoring in Tape Thickness When Choosing

Precision in material surfaces allows for thinner tape; greater disparities or textures require thicker tape (up to 50% mismatch). For large pieces, adhere to 2X tape thickness. Cover thermal expansion with 3X tape thickness.

- Strategizing for the Optimal Tape Usage

Plan adhesive usage with a converter for precise strips or measure material to minimize waste. For a 1 kg sign, use 430 mm, 29+0 mm, or 215 mm tape based on width. Predict future growth with documented material costs.

3m VHB Tape Application Guide

Here is a general guide for the application of 3M VHB tape:

1. Surface Preparation

Ensure that the surfaces to be bonded are clean, dry, and free of dust, dirt, grease, or other contaminants.

2. Application Technique

Apply firm and even pressure to ensure good contact between the tape and the surfaces. Use a roller or a similar tool to apply pressure evenly across the entire surface of the tape.

3. Handling Time

The handling strength of 3M VHB tape increases with time and temperature. However, some initial handling strength can be achieved immediately after application.

4. Curing Time

Full bond strength is usually achieved after 72 hours at room temperature. The bond strength will continue to increase over time.

5. Joint Design

Ensure that the joint design allows for proper stress distribution across the bonded area. Use sufficient tape width to accommodate the load requirements of the application.

6. Clean Removal

If removal is necessary, 3M VHB tape is designed to be cleanly removable, but the process may vary depending on the specific application.

How Do I Remove 3m VHB Tape From A Surface?

Here are some steps you can follow to remove 3M VHB tape from a surface:

1. Heat the Tape

Use a heat gun or a hairdryer to gently heat the surface of the tape. This helps to soften the adhesive and makes it easier to peel off.

2. Peel Off

Once the tape is heated, try to peel it off slowly and steadily. Use a plastic scraper or your fingernails to lift the edges.

3. Use Isopropyl Alcohol

If the tape is not coming off easily, you can use isopropyl alcohol. Apply a small amount of isopropyl alcohol to the adhesive residue and let it sit for a few minutes. This should help weaken the adhesive.

4. Rubbing Alcohol and Cloth

Moisten a cloth or cotton ball with rubbing alcohol and gently rub the adhesive residue. This can help dissolve the adhesive and make it easier to wipe away.

5. Commercial Adhesive Remover

If the above methods don’t work, you can try using a commercial adhesive remover. Follow the instructions on the product carefully.

Read Also Choosing the 3 Best Mastic Duct Sealant: A Comprehensive Guide

How to Store 3M VHB

Store 3M VHB adhesive tapes in an environment with a temperature of 20°C and 50% relative humidity for optimal performance. Ensure a cool, dry location to preserve the adhesive properties and longevity of the product.

FAQs

Can You Laser VHB Tape?

Yes, VHB tapes can be laser-cut using a 9.3 CO2 laser. This process provides precise cuts and is commonly employed for applications where accuracy and clean edges are essential.

Which 3m VHB tape is the strongest for car?

The 3M™ VHB™ Tape LSE Series is known for its high-strength bonding capabilities on low surface energy (LSE) substrates, making it suitable for automotive applications. Among the LSE Series, the 3M™ VHB™ Tape LSE-4950 is often considered one of the strongest choices for automotive bonding needs.

Which 3m VHB tape is the strongest for metal?

The 3M™ VHB™ Tape LSE Series is designed for bonding low surface energy substrates, but for maximum strength on metal surfaces, consider the 3M™ VHB™ Tape GPH Series. It offers high initial adhesion and excellent holding power on metals.

How Thick Is 3m VHB?

The 3M VHB (Very High Bond) tape with a thickness of 0.045 inch provides strong, durable bonds. Its thin profile belies its impressive strength, making it a versatile and reliable choice for various applications in industries such as construction and automotive.

Conclusion

Which 3m vhb tape is the strongest? The strength of 3M VHB tapes varies based on specific applications and requirements. Generally, the5952 VHB Tape is known for its high strength and durability, offering a strong bond for various surfaces. Selecting the appropriate tape depends on specific project needs and conditions.