Should I Use Dielectric Grease On Ignition Coils?

Should I use dielectric grease on ignition coils?

Yes, using dielectric grease on ignition coils can help prevent corrosion and improve electrical connections. It provides a protective barrier. In this discussion, we will explore the purpose of dielectric grease. Its potential advantages, and whether it is advisable to use it on ignition coils.

Ignition Coil Grease: AGS Dielectric Silicone Grease

This 4oz tube of dielectric grease is a must-have for enthusiasts and professionals alike. From spark plugs and ignition modules to sensor connections and battery terminals, this grease ensures optimal conductivity.

Features:

- OEM Specifications: Formulated to meet original equipment manufacturer standards, AGS Dielectric Silicone Grease guarantees compatibility and optimal performance for a wide range of electronic and standard ignition systems.

- High Energy Ignition Systems: This grease provides superior protection against moisture and corrosion, enhancing electrical connectivity and meeting OEM specifications.

- Moisture and Corrosion Resistance: Expertly crafted to create a robust barrier, the grease seals out moisture and corrosion, vital for maintaining the integrity of high-energy ignition systems, ensuring longevity and reliability.

Versatile Applications:

It is suitable for sensor connections, solenoids, truck pigtails, modules and coils, marine connections, lighting systems, batteries, and terminals.

Applications:

- Sensor connections

- Computer connections

- Solenoids

- Truck pigtails

- Ignition modules and coils

- Marine connections

- Lighting systems

- Batteries and terminals

Pros:

- Enhances performance and longevity of electronic and standard ignitions.

- Protects against moisture and corrosion, ensuring optimal conductivity.

- Meets OEM specifications for compatibility and performance.

- Specially designed for high-energy ignition systems.

- Versatile applications across automotive and marine settings.

- Reduces voltage leaks, improving electrical connectivity.

- Ideal for ensuring efficient ignition and engine performance.

Cons:

- Requires careful application to prevent excess usage.

- May not be suitable for certain specialized applications.

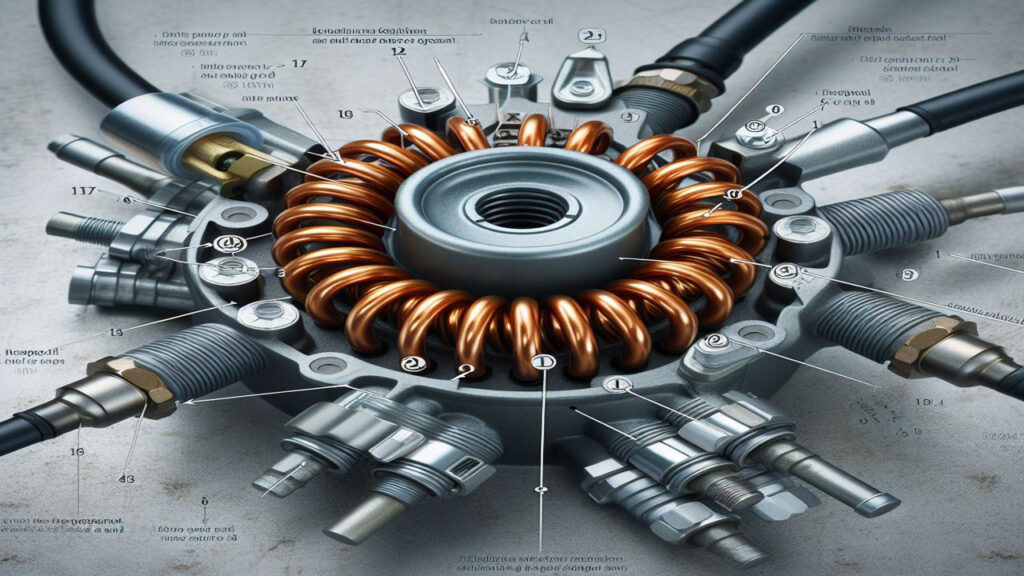

Where To Put Dielectric Grease On Ignition Coil?

Here’s where to apply it:

- Spark Plug Boot

- Spark Plug Terminal

- Ignition Coil Spring

Dielectric Grease On Ignition Coil – Advantage

Here are some advantages of using dielectric grease on ignition system components:

- Electrical Insulation: Dielectric grease is an insulating material that helps prevent the flow of electrical current.

- Corrosion Protection: Dielectric grease forms a protective barrier that helps prevent corrosion by sealing out moisture and inhibiting the formation of rust.

- Temperature Stability: It remains stable at both high and low temperatures, providing reliable protection for electrical connections in different operating conditions.

- Preventing Voltage Leaks: Dielectric grease helps create a barrier that prevents voltage leaks and arcing between electrical connectors.

- Ease of Disconnecting: When connectors are coated with dielectric grease, it can make it easier to disconnect them later.

Read More Enhance Performance with Dielectric Grease Spark Plug

Where Should You Not Use Dielectric Grease?

Here’s a rundown:

1. High-temperature

Those exceeding 500 degrees Fahrenheit (260 degrees Celsius).

2. Plastic or Rubber Components

Avoid applying it to spark plug boots, engine mounts, or any other plastic or rubber parts near the ignition system.

3. Sensor Connections

Applying grease to sensor connections can interfere with their ability to read and transmit data accurately. Keep it away from oxygen sensors, camshaft position sensors, and other sensitive components.

4. Headlamp Sockets

Applying grease to headlamp sockets can trap heat and potentially damage the bulbs or wiring. Stick to dry connections for your headlights.

5. Moving Parts

Grease can attract dirt and become abrasive, leading to premature wear and tear on moving parts. Resist the urge to grease things like door hinges or window regulator mechanisms.

Dielectric Grease On Coil Pack Connector

1. Ensure Clean Surfaces

Before applying the grease, make sure that the connector surfaces are clean and free of dirt, debris, or old grease. Clean the contacts with an appropriate electrical contact cleaner if necessary.

2. Apply a Thin Layer

Use a small amount of dielectric grease and apply a thin, even layer to the metal contacts of the connector. Avoid applying excessive amounts, as a little goes a long way.

3. Secure Connection

Once the grease is applied, reconnect the connector securely. The grease will help maintain a reliable electrical connection.

4. Avoid Excessive Use

While dielectric grease is beneficial, it’s important not to overapply it. Too much grease can attract dust and debris, potentially causing other issues.

5.Coil On Plug Boot

A coil-on-plug (COP) boot is a crucial component in your car’s ignition system. It plays a vital role in delivering the high voltage spark from the ignition coil to the spark plug, ensuring efficient combustion and engine performance.

Read Also 9 Best White Lithium Grease for Smooth, long lasting Operations

Ignition Coil Silicone Grease

Ignition coil silicone grease is a heat-resistant lubricant designed to protect and insulate ignition coils in vehicles. It helps prevent moisture ingress and ensures optimal electrical conductivity for efficient engine performance.

Where Do You Put Dielectric Grease On An Ignition Coil?

- Inside the spark plug boot: Apply a thin, pea-sized amount of grease to the inside of the boot, where it makes contact with the ceramic body of the spark plug.

- On the spark plug terminal: Apply a tiny amount of grease to the top of the spark plug terminal, just where the boot meets the metal.

- Optional: On some coil designs, there is a spring-like contact that sits atop the coil. You can apply a thin smear of grease to the inside of this spring where it touches the spark plug boot.

Do You Grease Ignition Coil

Yes, dielectric grease is often applied to ignition coil connectors and coil packs to prevent voltage leakage and improve electrical conductivity. It helps protect the components from moisture and corrosion.

Ignition Coil Boot Grease

Ignition coil boot grease is a dielectric compound applied to the spark plug boot and ignition coil connection. It prevents moisture and contaminants, ensuring a reliable electrical connection in automotive systems.

Using Dielectric Grease On Ignition Coil

Apply a tiny, pea-sized dab of high-quality dielectric grease to the inside of the boot, where it touches the ceramic body of the spark plug. Imagine a gentle handshake, not a smothering hug!

White Lithium Grease Ignition Coil

While white lithium grease is a versatile lubricant, it’s not recommended for use on ignition coils. Here’s why:

Reasons Not to Use White Lithium Grease on Ignition Coils:

- Electrical conductivity: White lithium grease is not a dielectric grease, meaning it conducts electricity to some extent. This can lead to leakage or short circuits in the high-voltage environment of the ignition system, causing misfires and engine problems.

- Heat resistance: While white lithium grease can handle moderate temperatures, it may not withstand the intense heat generated near the ignition coils and spark plugs. This can lead to the grease breaking down and losing its lubricating properties.

- Moisture resistance: White lithium grease is not as effective as dielectric grease in repelling moisture. Moisture can cause corrosion on the metal parts of the ignition coil and spark plug, leading to misfires and engine problems.

FAQs

Do I need to put dielectric grease on ignition coils?

Applying dielectric grease to ignition coil connections can help prevent corrosion and ensure proper electrical conductivity. It is recommended for maintaining a reliable and efficient ignition system.

Is dielectric grease necessary?

Dielectric grease is recommended for electrical connections to prevent corrosion and enhance conductivity. It helps protect against moisture, improving the longevity and performance of connections.

Should coil packs be greased?

Applying dielectric grease to coil pack connections can prevent corrosion, moisture ingress, and improve electrical conductivity. It’s generally recommended for better performance and longevity.

Should I put grease on spark plugs?

Greasing spark plugs isn’t necessary. However, a small amount of anti-seize compound on the threads can ease future removal. Avoid getting grease on the electrode or insulator.

Conclusion

The question of whether to use dielectric grease on ignition coils depends on various factors. While it can enhance electrical connections and prevent moisture, it’s crucial to follow manufacturer guidelines. Consult your vehicle’s manual and consider environmental conditions for optimal performance. Making informed decisions ensures your ignition system functions reliably.