Revolutionizing Bone Integration: Unleashing Mussel Magic for Unbreakable Implant Bonds

Titanium hip implants have long been plagued by loosening issues over time, necessitating premature replacements. To tackle this, a collaborative effort between the Fraunhofer Institute for Applied Polymer Research IAP, Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, and Fraunhofer USA Center for Manufacturing Innovation CMI has birthed a game-changing solution.

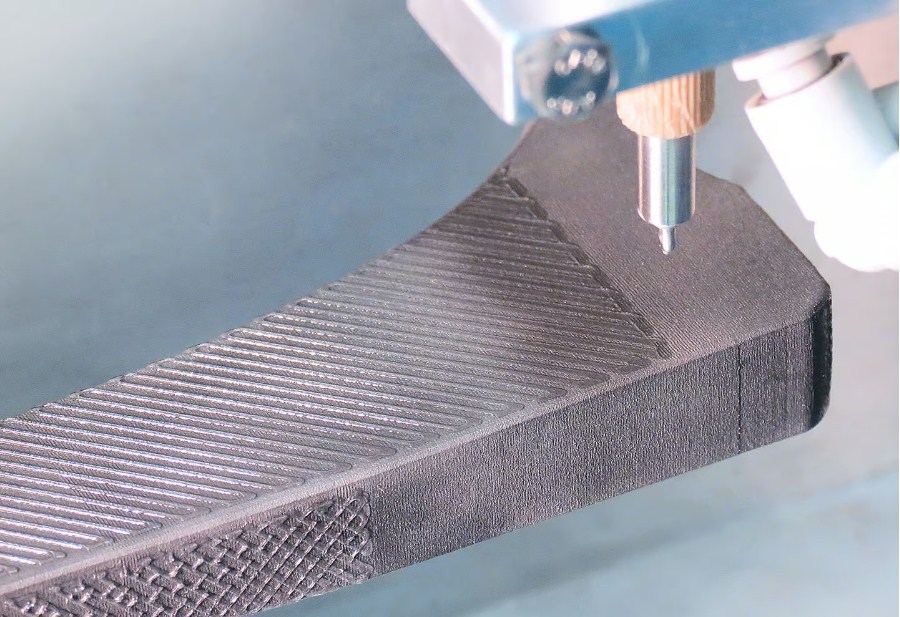

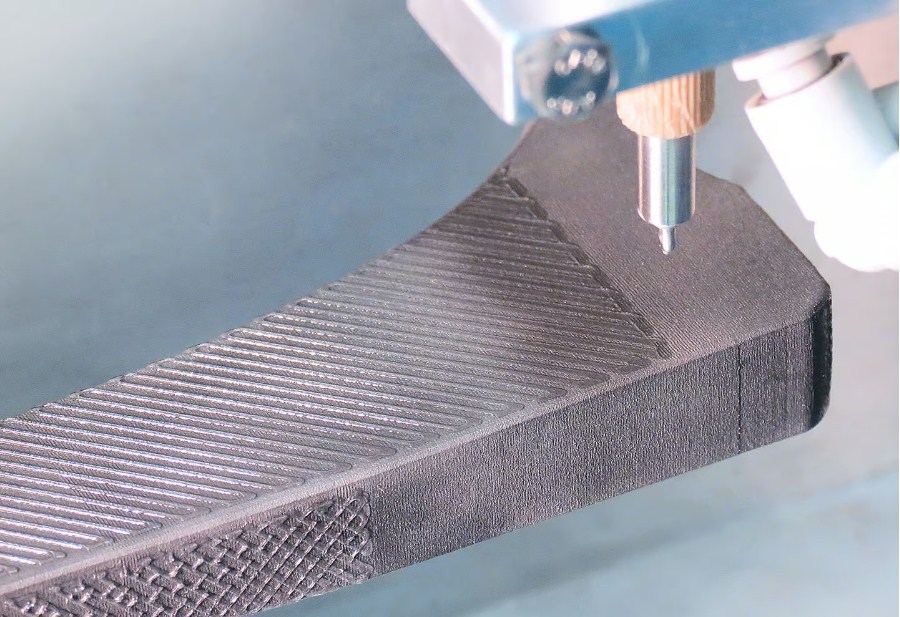

A printer applies the dopamine-based tissue adhesive to the three-dimensional titanium shaft of a hip joint

Their groundbreaking research introduces a biomimetic, antimicrobial tissue adhesive designed to extend implant longevity. Emulating the adhesive prowess of mussels, this innovative material, printable even on irregular surfaces, forms a seamless bond between the titanium implant and bone, potentially averting the need for early prosthesis replacements.

In a breakthrough collaboration between researchers at Fraunhofer IAP in Potsdam Science Park, Fraunhofer IGB, and Fraunhofer USA CMI, a biomimetic adhesive inspired by the tenacious grip of mussels is poised to revolutionize diverse applications in biomedicine. Focused on the adhesive qualities of a protein containing the amino acid dihydroxyphenylalanine (DOPA), the researchers have synthesized dopamine-based polymers to emulate this natural phenomenon.

This innovative adhesive exhibits extraordinary bonding capabilities, making it adaptable for various biomedical applications, including wound closure and enhancing the integration of titanium implants with bone surfaces. Dr. Wolfdietrich Meyer, a scientist at Fraunhofer IAP, highlights the adhesive’s unique properties, such as its ability to create a more natural appearance for implants, fostering improved healing processes and integration.

Moreover, the bio-based adhesive is sustainably produced and possesses antimicrobial properties, showcasing its potential for widespread use in advancing medical technologies. Beyond tissue adhesion, the dopamine-based polymers offer versatility, opening avenues for the development of functionalized surfaces, antibacterial materials, and intelligent coatings with specialized functions.

Unlocking a new frontier in adhesive technology, researchers at Fraunhofer IAP and IGB have pioneered photoreactive adhesives with remarkable versatility. Engineered through chemical synthesis, these adhesives can be tailored to react to light, specifically hardening upon exposure to UV rays. This photoreactive property enhances the adhesive effect, making it a game-changer for applications in 3D printing. Leveraging the capability to process photoreactive materials with UV radiation, the researchers have enabled the construction of intricate structures for personalized medical implants.

A significant breakthrough was achieved by the research team, as they successfully formulated a printable adhesive by cross-linking polymers. Dr. Meyer emphasizes the development of a 3D printing material, marking a pivotal step in advancing additive manufacturing. The application of this innovative adhesive was demonstrated using a bioprinter on the three-dimensional titanium shaft of a hip joint at the Fraunhofer USA Center for Manufacturing Innovation CMI in Boston, USA.

Looking ahead, the research team envisions enhancing control over adhesive properties, exploring solutions to activate and deactivate them as needed. This pursuit aims to provide surgeons with greater flexibility, allowing swift adjustments in case of misplacement and the ability to promptly deactivate the adhesive effect when required.

Source: Fraunhofer

- Fraunhofer Institute for Applied Polymer Research IAP (iap.fraunhofer.de)