5 Top Picks: The Ultimate Guide to the Best Glue for Vinyl Plank Flooring Installation

Choosing the right adhesive for vinyl plank flooring is crucial for a durable and long-lasting installation. The adhesive ensures a secure bond between the vinyl planks and the subfloor. The best glue for Vinyl Plank Flooring are Loctite 1360694 Vinyl Plank Flooring Adhesive, ROBERTS, Henry, DAP and Gorilla Heavy-Duty Adhesive. Opt for a thin layer of adhesive when installing Vinyl Flooring to ensure a smooth surface. This minimizes the visibility of any imperfections or bumps, facilitating a seamless fit between planks.

Using the correct glue enhances the overall stability and performance of the flooring, providing a smooth and resilient surface for years to come. Let’s check out our top-rated adhesives for vinyl floors list of the best glue for vinyl plank flooring.

Best Glue for Vinyl Plank Flooring

When choosing glue for vinyl plank flooring, opting for a durable and flexible adhesive for optimal results is crucial. Here is the list of the best glue down vinyl plank flooring reviews:

| Product | Main Feature | Check Price |

|---|---|---|

| Loctite 1360694 Vinyl Plank Flooring Adhesive | Quick setting | Check Price |

| ROBERTS Universal Vinyl Flooring Adhesive | Best adhesive for vinyl plank flooring on concrete | Check Price |

| Henry 430 Floor Tile Adhesive | Wide variety of applications | Check Price |

| DAP Multi-Purpose Floor Adhesive | Engineered with advanced technology | Check Price |

| Gorilla Heavy-Duty Adhesive | Long lasting bond, water activated, and polyurethane formula | Check Price |

5 Top Vinyl Plank Adhesive Reviews

1. Loctite 1360694 Vinyl Plank Flooring Adhesive

Loctite is the best adhesive brand for vinyl flooring. This adhesive is perfect for both residential and commercial applications.

Key Features

- Quick Setting

This waterproof vinyl glue sets in just under 10 minutes.

- Durability

Withstands torsion and bending, ensuring that your vinyl planks stay securely in place, even in high-traffic areas.

- Versatility

Suitable for various vinyl plank flooring types, making it a versatile choice for different installation projects.

- Reliable Bond

This creates a reliable and strong bond between the subfloor and vinyl planks, ensuring a stable and long-lasting installation.

- Indoor and Outdoor Use

Suitable for both indoor and outdoor applications, expanding its usability for a range of projects.

- Safe and Low Odor

Formulated with user safety in mind, this adhesive has a low odor, making it comfortable to work with during installation.

Pros

- The adhesive is user-friendly

- Versatile application for various vinyl plank flooring types.

- Withstands torsion and bending, ensuring durability in high-traffic areas.

- UV resistance protects against sunlight exposure, making it suitable for outdoor use.

- Suitable for both residential and commercial applications.

- Waterproof vinyl glue suitable for wading pools and other wet environments.

Cons

- A curing time of 24 hours may require some patience before the flooring can be subjected to heavy use.

2. Best adhesive for vinyl flooring on wood: ROBERTS Universal Vinyl Flooring Adhesive

This high-performance adhesive is specially formulated to provide a strong and durable bond for vinyl flooring applications. Whether you’re installing vinyl sheets or planks on various surfaces, this adhesive is designed to deliver exceptional results.

Key Features

- Moisture-Resistant Formula

This feature ensures a reliable bond even in spaces with varying humidity levels.

- Eco-Friendly Vinyl Adhesive

This adhesive is crafted with eco-friendly materials, minimizing its environmental impact. Choose sustainability without compromising on performance.

- Moisture Control

Tackle moisture-related challenges head-on with the moisture control capabilities of this adhesive.

- Versatile Application

Designed for flexibility, this adhesive is suitable for various vinyl flooring applications.

Pros

- Long-Lasting Bond

- Versatility

- Environmentally Responsible

- Moisture Protection

- User-Friendly Application

- Vinyl-to-vinyl floor transition adhesive

Cons

- Suitable for only indoor use

3. Henry 430 Floor Tile Adhesive

This adhesive stands out among the best adhesive brands for vinyl flooring, providing a reliable solution for both residential and commercial applications. With a focus on durability and ease of use, it ensures a secure and lasting bond.

Key Features

- Moisture Control

Henry 430 incorporates advanced moisture control technology, making it an ideal choice for installations in areas prone to dampness or moisture, such as basements or bathrooms.

- Quick Grab Formula

This adhesive boasts a quick-grab formula, allowing for efficient and hassle-free installations.

- Versatile Application

Henry 430 is suitable for a variety of vinyl flooring types, including luxury vinyl tiles (LVT), vinyl plank flooring, and vinyl composition tile (VCT).

- Low VOC Formula

With a low volatile organic compound (VOC) formula, this adhesive prioritizes indoor air quality. It meets environmental standards while providing a secure bond for your vinyl floor.

Pros

- Henry 430 creates a resilient and long-lasting bond

- Easy application

- The moisture control feature prevents issues related to moisture damage,

- Wide compatibility

Cons

- Not Ideal for Outdoor Use

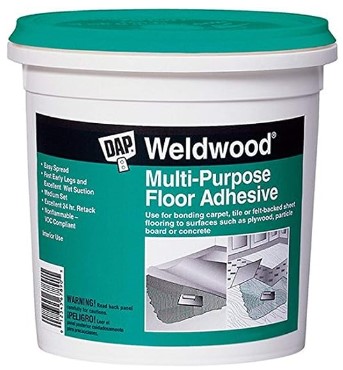

4. Best glue for vinyl plank flooring on concrete :DAP Multi-Purpose Floor Adhesive

DAP is the Best adhesive to glue vinyl floor w/ foam backing to plywood. Whether you’re installing vinyl, carpet, or other flooring materials, this adhesive ensures a strong and lasting bond.

Key Features

- High-Strength Bonding

DAP Multi-Purpose Floor Adhesive offers a powerful bond, securely attaching flooring materials to subfloors for long-lasting durability.

- Moisture Control

These luxury vinyl plank flooring adhesives include moisture-resistant properties. It prevents issues related to water damage and ensures a reliable bond even in humid conditions.

- Low Odor

With a low-odor formula, this adhesive provides a more pleasant and comfortable working environment during installation.

Pros

- Reducing the likelihood of issues such as lifting or shifting

- Enhanced moisture resistance

- The quick-grab formula allows for a faster application process.

- The adhesive’s versatility makes it suitable for various flooring materials.

Cons

- Proper storage conditions are crucial. As exposure to extreme temperatures or prolonged storage can impact the adhesive’s effectiveness.

5. Glue for vinyl plank flooring repair Gorilla Heavy-Duty Adhesive

This adhesive is engineered to provide unparalleled strength and versatility, ensuring a lasting bond on various surfaces. Whether you’re working on DIY projects, home repairs, or professional applications, Gorilla Heavy-Duty Adhesive is the go-to choice.

Key Features

- Unrivaled Strength

Gorilla Heavy-Duty Adhesive boasts an exceptionally strong bond, making it ideal for heavy-duty projects and demanding applications.

- Waterproof Reliability

Rest easy knowing that your bonds are protected against the elements. Gorilla Heavy-Duty Adhesive is waterproof, providing durability even in challenging environments.

- Sandable Finish

Achieve a flawless, polished look with Gorilla Heavy-Duty Adhesive. Sandable for a smooth finish, this adhesive allows you to refine your projects to perfection.

- Paintable Perfection

Customize your projects effortlessly. Gorilla Heavy-Duty Adhesive is paintable. This allows you to match your creations to any color scheme or aesthetic.

- VOC Compliant

Gorilla cares about your health and the environment. Our Heavy-Duty Adhesive is VOC compliant, ensuring a low environmental impact while maintaining high performance.

Pros:

- All-Surface Compatibility

- Long-Lasting Durability

- Easy to Sand

- Customization with Paint

- Low Environmental Impact

Cons

- Not suitable for use on, polypropylene, polyethylene, and bitumen.

Read More About Do You Need Transition Strips For Vinyl Flooring: Expert Opinion

Another Best glue for vinyl plank flooring seams is Armstrong S-761 8 oz. Floor Seam Adhesive

Benefits of vinyl plank flooring for home

- Affordability: Vinyl plank flooring is often more budget-friendly than other flooring options like hardwood or stone, making it a cost-effective choice for homeowners.

- Versatility: Vinyl planks come in a variety of styles, colors, and patterns, allowing homeowners to achieve the desired aesthetic for any room in their home.

- Durability: Vinyl flooring is resistant to scratches, stains, and water, making it an excellent option for high-traffic areas, kitchens, and bathrooms. It is also less prone to damage from pets or heavy furniture.

- Easy Maintenance: Vinyl plank flooring is easy to clean and maintain. Regular sweeping and occasional mopping are usually sufficient to keep it looking new.

- Comfort underfoot: Compared to harder flooring surfaces like tile or hardwood, vinyl is softer, providing a more comfortable feel underfoot. Some vinyl planks also have additional padding for added comfort.

- DIY-Friendly Installation: Many vinyl plank options come with click-and-lock or adhesive backing systems, making them suitable for homeowners who prefer to take on a do-it-yourself approach to flooring installation.

- Resistant to Allergens: Unlike carpets, vinyl flooring doesn’t harbor allergens like dust and pet dander, making it a preferable choice for individuals with allergies.

- Temperature Stability: Vinyl is less susceptible to temperature changes compared to natural materials like hardwood, ensuring stability and minimizing the risk of warping or expansion.

- Environmentally Friendly Options: Some vinyl plank flooring is made with eco-friendly materials, and certain manufacturers offer products that are recyclable or made from recycled content.

- Longevity: When properly installed and maintained, vinyl plank flooring can have a long lifespan, providing a durable and attractive flooring solution for years to come.

Types Of Glue For Vinyl Plank Flooring

Here is the list of adhesives for vinyl floors:

- Pressure-Sensitive Adhesive

A versatile choice for vinyl plank flooring, this adhesive creates a bond upon application of pressure, ensuring easy installation.

- Hard-Set Adhesive

Ideal for permanent installations, hard-set adhesives provide a strong bond, making them suitable for high-traffic areas and heavy furniture.

- Epoxy-Based Adhesive

Known for its durability, epoxy adhesive offers a strong, long-lasting bond for vinyl plank flooring, ensuring stability and resilience over time.

- Waterproof Adhesive

Specifically formulated to resist moisture, waterproof adhesives safeguard against water damage, making them suitable for areas prone to spills or high humidity.

- Low VOC Adhesive

Environmentally friendly, low VOC adhesives emit minimal volatile organic compounds, ensuring a healthier indoor air quality while securing vinyl plank flooring effectively.

- Subfloor Preparation

Adhesives designed for subfloor preparation enhance bonding and prevent issues like uneven surfaces, ensuring a smooth and durable foundation for vinyl plank flooring.

- Room Conditions

Consider adhesives tailored to room conditions, such as temperature and humidity, to guarantee optimal performance and a secure bond for vinyl plank flooring.

- LVP Flooring Type

Some adhesives are specifically formulated for luxury vinyl plank (LVP) flooring, providing the necessary properties to ensure a strong and lasting connection.

- Tarkett Adhesives

Tarkett offers adhesives designed to complement their vinyl plank flooring products, ensuring compatibility and optimal performance in various applications.

- Mapei Adhesives

Mapei provides a range of adhesives suitable for vinyl plank flooring, offering solutions that cater to different needs, including waterproof and low VOC options.

Drying Time For Vinyl Flooring Adhesive

Specific Considerations For Applying Glue For Vinyl Plank Flooring

Here are specific considerations for applying glue for vinyl plank flooring:

- Clean and Dry Surface

Ensure the subfloor is clean, dry, and free from dust, dirt, grease, and other contaminants. Any debris on the subfloor can affect the adhesive bond.

- Smooth and Level Subfloor

Repair any imperfections in the subfloor, such as cracks or uneven surfaces, to create a smooth and level foundation for the vinyl planks.

- Moisture Testing

Conduct a moisture test on the subfloor to ensure it meets the manufacturer’s specifications. Excessive moisture can compromise the adhesive bond, leading to problems like buckling or mold growth.

- Subfloor Compatibility

Check if the subfloor material is suitable for vinyl plank installation. Certain materials may require additional preparation or the use of specific primers to enhance adhesion.

- Acclimate Vinyl Planks

Allow the vinyl planks to acclimate to the room’s temperature and humidity levels before installation. This helps prevent expansion or contraction after installation.

Read Also 5 Best Adhesive for Vinyl Plank Flooring on Stairs: A Detailed Guide

DIY Vinyl Flooring Adhesive Application

Here’s a step-by-step guide to help you through the process:

Materials and Tools

- Vinyl plank flooring

- Flooring adhesive

- Trowel with the recommended notch size

- Chalk line

- Measuring tape

- Utility knife

- Broom or vacuum cleaner

- Damp cloth or sponge

Step 1: Prepare the Subfloor

Ensure that the subfloor is clean, dry, and level. Remove any debris, dust, or dirt using a broom or vacuum cleaner.

Step 2: Acclimate the Flooring

Allow the vinyl planks to acclimate to the room for at least 48 hours before installation.

Step 3: Establish a Starting Point

Use a chalk line to establish a straight starting line. This line will guide the placement of the first row of vinyl planks. Make sure the line is square to the walls.

Step 4: Apply the Adhesive

Apply the adhesive in small, manageable sections to prevent it from drying before you lay the vinyl planks.

Step 5: Use the Correct Notch Size

Make sure to use the trowel with the correct notch size recommended by the adhesive manufacturer. The size of the notch will depend on the type and brand of adhesive you’re using.

Step 6: Install the Vinyl Planks

Place the first row of vinyl planks along the chalk line, using spacers to maintain an expansion gap around the perimeter. Press the planks firmly into the adhesive.

Step 7: Continue Installation

Continue applying adhesive and installing vinyl planks row by row. Stagger the end joints of adjacent rows for a more natural appearance. Press each plank firmly into the adhesive to ensure a strong bond.

Step 8: Trim as Needed

Use a utility knife to trim the planks at the edges and around obstacles.

Step 9: Clean Excess Adhesive

Wipe off any excess adhesive from the surface of the vinyl planks immediately using a damp cloth or sponge.

Step 10: Allow Time to Cure

Allow the adhesive to cure according to the manufacturer’s recommendations before walking on or placing heavy objects on the floor.

Read More About Low VOC Adhesive Market Poised for Exponential Growth

Vinyl Plank Flooring Glue Application Tips

Here are some tips to help you with the process:

- Always start by carefully reading and following the manufacturer’s installation instructions.

- The subfloor must be clean, dry, and smooth before applying glue.

- Use the right adhesive

- Allow the vinyl planks to acclimate to the room’s temperature and humidity for at least 48 hours before installation.

- Be consistent with the application to ensure proper bonding.

- It’s advisable to work in small sections at a time

- Once the adhesive is applied, install the vinyl planks immediately.

- After installing the planks, use a floor roller to go over the entire floor.

- Wipe away any excess adhesive on the surface of the planks immediately.

- Follow the recommended drying time.

Common Mistakes

- Not Reading Manufacturer Guidelines

- Using the Wrong Type of Adhesive

- Inadequate Subfloor Preparation

- Incorrect Trowel Size

- Not Allowing Sufficient Open Time

- Applying Too Much or Too Little Adhesive

- Ignoring Room Temperature and Humidity

- Not Rolling the Flooring After Installation:

- Neglecting Expansion Gaps

- Skipping a Dry Run

Removing Adhesive From Vinyl Plank Flooring

Removing adhesive from vinyl plank flooring requires careful attention to avoid damaging the floor’s surface. Here are some steps you can follow:

Gather Materials

- Soft cloths or rags

- Isopropyl alcohol

- Water

- Plastic putty knife or scraper

- White vinegar (optional)

Scrape off Excess Adhesive

Use a plastic putty knife or scraper to gently scrape off as much of the adhesive as possible. Be cautious not to scratch the floor.

1. Soak the adhesive

Moisten a soft cloth or rag with isopropyl alcohol or a mixture of water and white vinegar (equal parts). This helps to loosen the adhesive.

2. Rubbing or Blotting

After the adhesive has softened, gently rub or blot the area with the cloth. If the adhesive is particularly stubborn, you may need to apply more alcohol or vinegar mixture and let it sit for a longer period before attempting to rub or blot again.

3. Clean the Floor

Once the adhesive is removed, clean the area with a mild detergent or a vinyl floor cleaner to eliminate any residue.

4. Dry the Floor

Dry the cleaned area completely with a clean, dry cloth to prevent slipping.

The Importance Of Low VOC And Eco-Friendly Adhesives For Indoor Air Quality

Low VOC and eco-friendly vinyl plank flooring adhesives are crucial for maintaining indoor air quality. Volatile Organic Compounds (VOCs) emitted by traditional adhesives can contribute to air pollution and health issues.

Choosing low-VOC alternatives helps reduce harmful emissions, promoting a healthier indoor environment and minimizing the impact on both occupants and the planet.

Glue Vs Click Vinyl Flooring Installation

Each installation method has its own set of advantages and considerations:

1. Glue-Down Vinyl Flooring

Installation Process

In this method, the vinyl planks or tiles are glued directly to the subfloor using a special adhesive. This creates a permanent bond between the flooring and the subfloor.

Advantages

- Stability: Glue-down installation provides a stable and secure floor, which is especially important in high-traffic areas.

- Durability: The glued-down flooring tends to be more resistant to movement or shifting over time.

- Suitable for Irregular Subfloors: This method is suitable for subfloors with minor irregularities, as the glue helps to create a level surface.

2. Click Vinyl Flooring

Installation Process

Click vinyl flooring, also known as floating vinyl, features a locking mechanism that allows the planks or tiles to click and lock into place without the need for glue. This type of installation creates a “floating” floor that sits on top of the subfloor without being attached.

Advantages

- DIY-Friendly: Click vinyl is often considered more DIY-friendly since it doesn’t require specialized adhesives, and the locking system simplifies installation.

- Ease of Replacement: If a plank or tile becomes damaged, it can be relatively easy to remove and replace without affecting the entire floor.

- Quick Installation: Click vinyl flooring can be installed more quickly than glue-down options.

FAQ

What is the best adhesive for vinyl plank flooring on concrete?

Acrylic-based adhesives are recommended for vinyl plank flooring on concrete due to their strong bonding properties and moisture resistance.

Can I use regular glue for vinyl plank flooring?

No, it’s not recommended. Use adhesive specified for vinyl flooring to ensure proper installation and prevent damage to the material.

How long does it take for vinyl plank flooring adhesive to dry?

Vinyl plank flooring adhesive typically takes 12 to 20 hours to dry completely, ensuring a secure and durable bond.

Can I glue vinyl plank flooring over existing tile?

Yes, you can glue vinyl plank flooring over existing tile, but it’s crucial to ensure a clean, smooth surface for adhesion.

What is the best adhesive for luxury vinyl plank flooring?

Suggested adhesive for luxury vinyl plank flooring: Use a high-quality, moisture-resistant LVP adhesive for optimal durability and installation performance.

Are there eco-friendly adhesives for vinyl flooring?

Yes, ALSEAL offers eco-friendly adhesives for vinyl flooring, providing a sustainable and responsible choice for environmentally conscious consumers and businesses.

Is it necessary to use a moisture-resistant adhesive for vinyl flooring?

Yes, using a moisture-resistant adhesive is essential for vinyl flooring to prevent damage and ensure long-lasting adhesion in humid conditions.

Can I use a double-sided tape instead of glue for vinyl planks?

Yes, you can use double-sided tape for vinyl planks instead of glue, providing a secure and adhesive bond for installation.

Conclusion

In conclusion, selecting the best glue for vinyl plank flooring is crucial for a successful and durable installation. With a myriad of options available, it’s essential to consider factors such as adhesion strength, ease of application, and compatibility with vinyl materials. By exploring the top recommendations provided in this guide, you can ensure a reliable and long-lasting bond for your vinyl plank flooring project.