Ep 0 Grease Equivalent: Ultimate Guide to Maximum Lubrication Efficiency

Ep 0 grease equivalent lists are given below

Amoco Oil Co. – Rykon Grease #0 EP

• BP Oil Co.- Energrease LS-EP0

• Cheron U.S.A., Inc. -Dura-Lith EP0

• Citgo Petrol-Premium Lithium Grease EP0

• Conoco Inc. -EP Conolith Grease #0

• Exxon Company U.S.A. Lidok EP0

• Kendall Refining Co.-Lithium Grease L-406

• Mobil Oil Corp. -Mobilux EP0

• Petro-Canada-Multipurpose Lotemp EPGrease

• Shell Oil Co. -Alvania EP Grease RO

• Shell Canada LTD -Alvania Grease EPW

• Sun Oil Co. -Sun Prestige 740 EP

• Texaco Lubricants-Multifak EP0

• Unocal 76 (East & West) Unoba EP0.

Ep-0 grease usually means grease with Extreme Pressure (EP) additives to enhance performance under high-pressure conditions.

The individual has Cenex NLGI 0 corn head grease, which lacks the EP label. They plan to use this grease and consider pumping three tubes of the first available NLGI 0 grease and running it, likely for equipment maintenance purposes. It is a low-viscosity oil used for specific applications.

One specific type of grease, known as ep 0 grease, stands out from the rest because it is not actually equivalent to grease. Instead, ep 0 grease refers to a low-viscosity oil that is specifically designed for certain applications. This article will explore ep 0 grease in more detail, highlighting its properties and applications in various industries.

Understanding The Importance Of Ep 0 Grease

Ep 0 grease is a specialized type of lubricant used in various mechanical applications to reduce friction and ensure smooth operation. If you’re wondering what ep 0 grease is all about and why it is important, this section will provide you with all the essential information.

What Is Ep 0 Grease?

Ep 0 grease, also known as extreme pressure grease, is a type of lubricating grease that belongs to the nlgi (national lubricating grease institute) grade 0 classification. It is specifically designed to handle heavy-duty applications that involve high loads, shock loads, and extreme temperatures.

EP grease, short for Extreme Pressure grease, is designed to withstand heavy loads and high-pressure conditions. It’s formulated with additives that provide superior lubrication under extreme circumstances, such as metal-to-metal contact and high loads. EP 0 grease, therefore, has a relatively low consistency, allowing it to flow and distribute within machinery components, ensuring adequate lubrication even in hard-to-reach areas.

This grease type is formulated with a combination of base oils, thickeners, and additives to provide superior lubrication and formulated to provide extra protection.

Definition And Purpose Of Ep 0 Grease

Ep 0 grease can be defined as a highly viscous and adhesive lubricant that is used in applications where conventional greases fail to perform optimally. Due to its unique formulation, ep 0 grease offers exceptional load-carrying capabilities, excellent resistance to oxidation, and remarkable thermal stability.

The key purpose of ep 0 grease is to lubricate and protect various components, including bearings, gear boxes, bushings, and slides. It forms a protective film that prevents metal-to-metal contact, reducing friction and wear. This results in extended equipment life, reduced maintenance costs, and improved operational efficiency.

Ep 0 grease offers several advantages over other lubricants:

- Load-carrying capacity: Ep 0 grease can withstand high pressure and heavy loads, making it suitable for applications with extreme operating conditions.

- Temperature resistance: The specialized formulation of ep 0 grease enables it to perform effectively at both high and low temperatures, providing consistent lubrication regardless of the operating environment.

- Water resistance: Ep 0 grease exhibits good resistance to water washout, ensuring reliable lubrication even in wet or humid conditions.

- Oxidation resistance: Ep 0 grease contains additives that protect against oxidation and maintain its performance over time, reducing the likelihood of premature component failure.

Why Ep 0 Grease Is Essential For Maximum Lubrication Efficiency

Ep 0 grease is essential for achieving maximum lubrication efficiency due to its unique properties and capabilities. Here’s why it should be a preferred choice for your lubrication needs:

- Enhanced protection: Ep 0 grease forms a lubricating film that minimizes friction and wear, thereby protecting vital components from damage and extending their lifespan.

- Reduced downtime: By using ep 0 grease, you can minimize equipment failures and unplanned downtime, leading to increased productivity and cost savings.

- Improved energy efficiency: The reduced friction provided by ep 0 grease contributes to lower energy consumption, as less power is required to overcome resistance and maintain smooth operation.

- Optimal performance in demanding conditions:

- Ep 0 grease’s ability to handle heavy or shock loading and temperature variations ensures reliable lubrication even under challenging operating conditions.

- Extended Bearing Life: EP 0 grease creates a protective barrier that reduces friction and minimizes heat generation within bearings. This extended bearing life potential results in cost savings and reduced downtime.

- Extra Wear Protection: Its extreme pressure (EP) properties provide extra protection against wear, especially in applications with high unit pressures or shock loads. This ensures the equipment’s longevity and reliability.

- Ep 0 grease offers superior lubrication and protection for heavy-duty applications, allowing for high performance, increased equipment lifespan, and reduced maintenance costs. By understanding the importance of ep 0 grease and utilizing it appropriately, you can ensure the smooth and efficient operation of your mechanical systems.

Read More About B7000 Glue Vs E6000: A Comprehensive Comparison

What Is The Difference Between Ep2 And Ep 0 Grease?

Here’s a table summarizing the key differences between EP2 and EP0 greases:

| Property | EP2 Grease | EP0 Grease |

| NLGI Grade | NLGI 2 | NLGI 0 |

| Consistency | Moderately thick | Soft |

| Thickener Type | Lithium complex | Lithium or lithium complex |

| Application | General-purpose | Low-temperature or high-speed |

| Load-Carrying Capacity | Good | Lower than EP2 |

| Temperature Range | Moderate to high | Low to moderate |

| Water Resistance | Good | Fair to good |

| Common Applications | Automotive, industrial | Low-temperature, low-speed |

| equipment, machinery | applications, electric motors |

Ep 0 Grease Specifications

EP 0 grease, also known as Extreme Pressure (EP) Grade 0 grease, is a type of lubricating grease used in various industrial applications. Here’s a table outlining some common specifications and characteristics of EP 0 grease:

| Property/Specification | EP 0 Grease |

| NLGI Grade | 0 |

| Thickener Type | Lithium or Lithium Complex |

| Base Oil Type | Mineral or Synthetic |

| Temperature Range (°C) | -20 to 120 (for mineral oil-based grease) |

| -50 to 150 (for synthetic oil-based grease) | |

| Dropping Point (°C) | Typically above 180 (for lithium-based) |

| Typically above 260 (for lithium complex) | |

| Worked Penetration (ASTM D217) | 355-385 |

| Color | Brown or Off-White |

| Consistency | Smooth and Buttery |

| EP Additives | Yes (for extreme pressure applications) |

| Water Resistance | Fair to Good |

| Corrosion Protection | Good |

| Oxidation Resistance | Fair to Good |

| Compatibility | Compatible with most other greases |

| Typical Applications | – General-purpose industrial lubrication |

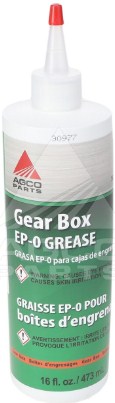

Mobilux Ep 0 Grease Equivalent

Mobilux ep0 grease is equivalent to Crown Grease EP 0 35.2 Pound Pail, Multis EP 0, Energrease LS EP 0, Alvania EP 0, and Chevron Multifak EP 0 grease, all of which share similar performance characteristics and applications.

What Is The Concept Of “Grease Equivalent” In Industrial Applications?

In industrial applications, “grease equivalent” refers to a measure of a lubricant’s performance comparable to that of grease. It helps determine the suitability of alternative lubricants, such as oils or solid lubricants, in specific machinery or equipment.

What Are The Factors That Influence The Calculation Of “Grease Equivalent” For Various Lubricants?

The calculation of “Grease Equivalent” for various lubricants is influenced by several factors, including viscosity, temperature, operating conditions, load, and the specific application requirements. These factors help determine the suitable grease with the right consistency, base oil type, and additives to ensure optimal lubrication and performance in a given machinery or system.

How Do You Convert Between Different Grease Specifications Or Grades?

Converting between different grease specifications or grades can be done by following these steps:

- Identify the current grease specification and grade you are using.

- Obtain the technical data or specifications for the desired grease grade.

- Compare key properties such as viscosity, base oil type, thickener type, and additives between the two greases.

- Ensure the new grease meets or exceeds the requirements of your application.

- If the properties match, proceed with the conversion.

- If there are differences, consult with a lubrication specialist to determine if adjustments or compatibility testing are needed.

- Implement the new grease carefully, ensuring proper lubrication practices are maintained.

Factors To Consider When Choosing Ep 0 Grease Equivalent

Let’s delve into the key considerations when choosing the right ep 0 grease equivalent:

Temperature Resistance And Stability

- Grease performance can be significantly impacted by high and low temperatures.

- Extreme temperatures can cause grease to become too thin or too thick, affecting its ability to lubricate effectively.

- Selecting an ep 0 grease that can withstand extreme temperatures is vital for maintaining optimal performance.

The Impact Of High And Low Temperatures On Grease Performance

- High temperatures can lead to grease degradation, resulting in reduced lubrication effectiveness and potential equipment damage.

- Low temperatures can cause grease to solidify or become too viscous, hindering its ability to provide lubrication.

- Ensuring your ep 0 grease is capable of handling both high and low temperatures is crucial for reliable performance.

How To Select An Ep 0 Grease That Can Withstand Extreme Temperatures

- Look for ep 0 greases with a wide operating temperature range specified by the manufacturer.

- Consider the application’s temperature requirements and choose a grease that can handle the extremes.

- Opt for greases formulated with additives that enhance temperature stability and provide exceptional lubrication performance.

Load-Carrying Capacity

- The load-carrying capacity of grease is essential, especially in applications where heavy loads are present.

- Grease with insufficient load-carrying capacity may result in premature wear and equipment failure.

- It is crucial to select an ep 0 grease that can handle the specific load requirements of your application.

The Importance Of Grease’S Ability To Handle Heavy Loads

- Grease must possess superior load-carrying capacity to withstand the forces exerted in heavy-load applications.

- Without adequate load-carrying capacity, grease can fail, leading to increased friction and wear on critical components.

Factors To Consider When Determining The Load-Carrying Capacity Of Ep 0 Grease

- Check the manufacturer’s specifications for the grease’s load-carrying capacity rating.

- Consider the application’s load demands, including static and dynamic loads.

- Ensure the chosen ep 0 grease can handle the maximum load requirements with a sufficient safety margin.

Water Resistance

- Water can have detrimental effects on grease performance, leading to corrosion, washout, and loss of lubrication.

- Selecting an ep 0 grease with excellent water resistance properties is crucial for applications exposed to moisture or water ingress.

How Water Can Impact Grease Performance

- Water can contaminate grease, altering its consistency and reducing its lubricating properties.

- Water can cause rust and corrosion, leading to equipment damage and decreased performance.

Oxidation Stability

- Oxidation can occur when grease comes into contact with oxygen, leading to degradation and reduced performance.

- Ep 0 greases with high oxidation stability are crucial for ensuring long-lasting lubrication and preventing premature failure.

Understanding The Effects Of Oxidation On Grease

- Oxidation can cause grease to deteriorate, leading to increased friction, reduced lubrication, and potential equipment damage.

- High temperatures and exposure to air can accelerate the oxidation process, making it vital to choose an ep 0 grease with excellent oxidation stability.

Selecting An Ep 0 Grease With High Oxidation Stability

- Look for greases formulated with antioxidants that inhibit oxidation and extend the grease’s service life.

- Consider the application’s operating conditions, including temperature and exposure to oxygen, to determine the level of oxidation stability required.

- Choosing an ep 0 grease with superior oxidation stability helps ensure long-term performance and equipment protection.

The Importance Of Ensuring Compatibility Between Grease And Materials

- Incompatible grease can cause corrosion, swelling, or softening of materials, compromising their structural integrity.

- Proper material compatibility prevents potential failures and extends the lifespan of equipment.

Factors To Consider When Choosing An Ep 0 Grease That Works Well With Different Materials

- Check the manufacturer’s recommendations for material compatibility.

- Consider the application’s material requirements, such as seals, gaskets, and bearings.

- Consult with experts or conduct compatibility tests to ensure the grease chosen is suitable for all materials involved.

By considering these factors, you can make an informed decision when selecting an ep 0 grease equivalent that meets the specific requirements of your application. Always refer to the manufacturer’s guidelines and consult with experts for further assistance in choosing the right grease.

Read Also Loctite Blue Vs Red: Which One Is Stronger?

Best Practices For Applying Ep 0 Grease Equivalent

Proper lubrication techniques:

- To ensure effective lubrication, apply ep 0 grease equivalent using the appropriate method

- Follow the manufacturer’s instructions for application and equipment specifications

Importance of following manufacturer’s instructions:

- Manufacturer’s instructions provide specific guidelines for applying ep 0 grease equivalent

- Following these instructions ensures optimal performance and extends equipment lifespan

Tips for ensuring accurate and efficient lubrication:

- Clean and inspect lubrication points before applying ep 0 grease equivalent

- Use the correct tools for the job, such as grease guns or automated lubrication systems

- Apply the grease evenly and avoid over or under lubrication to prevent damage

- Regularly check and adjust lubrication intervals based on equipment usage and conditions

Frequency of application:

- Ep 0 grease equivalent should be applied at regular intervals for proper equipment maintenance

- Following a maintenance schedule recommended by the manufacturer ensures consistent lubrication

Determining the ideal lubrication frequency for maximum efficiency:

Factors that may affect the frequency of ep 0 grease application:

- Equipment type and design

- Operating conditions (temperature, load, speed)

- Environment (dust, moisture, chemicals)

- Equipment age and condition

Lubrication points to consider:

- Identify crucial lubrication points in various machinery and equipment

- These points include bearings, gears, seals, and joints

- Refer to equipment manuals or consult with experts to locate specific lubrication points

How to effectively apply ep 0 grease to these points:

- Clean the lubrication point of any dirt or debris

- Apply the appropriate amount of ep 0 grease equivalent using the recommended method

- Ensure even distribution of the grease to maximize lubrication effectiveness

Monitoring and maintenance:

- Regular monitoring and maintenance of lubrication systems is crucial

- Check for signs of insufficient lubrication such as increased friction, overheating, or unusual noise

- Address any issues promptly by adding more ep 0 grease or adjusting the lubrication frequency

Common Issues And Troubleshooting Tips

Ep 0 Grease Equivalent: Common Issues And Troubleshooting Tips

Over-Greasing

Over-greasing is a common issue when it comes to lubricating machinery and equipment with ep 0 grease. Here are the key points to keep in mind:

- The negative effects of over-greasing:

- Excess grease can cause increased friction and resistance, leading to higher energy consumption and increased operating temperatures.

- Over time, the excess grease can push out the seals, leading to leakage and potential contamination.

- How to prevent over-greasing when using ep 0 grease:

- Follow the manufacturer’s recommended lubrication schedule and quantity guidelines.

- Utilize automated lubrication systems to ensure accurate grease application.

- Regularly inspect equipment for signs of excess grease buildup.

Under-Greasing

Under-greasing is equally problematic and can result in machinery and equipment breakdowns. Consider the following points:

- The consequences of under-greasing machinery and equipment:

- Insufficient lubrication leads to increased friction, which can cause wear and tear on moving parts.

- Without proper lubrication, components may seize or fail prematurely, resulting in costly repairs or replacements.

- Troubleshooting tips for addressing under-greasing issues:

- Regularly monitor equipment to identify signs of insufficient lubrication, such as strange noises or increased temperatures.

- Conduct thorough inspections to ensure all lubrication points are adequately greased.

- Adjust the lubrication schedule to match the specific requirements of your machinery and equipment.

Contamination And Cross-Contamination

Contamination can significantly impact the performance of ep 0 grease. Consider the following points related to contamination and cross-contamination:

- How contamination can affect ep 0 grease performance:

- Contaminants like dirt, debris, or water can compromise the grease’s viscosity and lubricating properties.

- If the grease becomes contaminated, it may no longer provide sufficient protection, leading to accelerated wear on equipment components.

- Preventive measures to avoid contamination and cross-contamination:

- Regularly clean lubrication points and surrounding areas to prevent dirt and debris from entering.

- Use proper sealing mechanisms to minimize water intrusion.

- Use compatible greases when lubricating equipment to prevent cross-contamination.

Storage And Shelf Life

Proper storage and understanding the shelf life of ep 0 grease are crucial for maintaining its performance. Consider the following tips:

- Proper storage techniques for ep 0 grease:

- Store grease containers in a cool, dry, and clean environment away from direct sunlight.

- Ensure containers are tightly sealed to prevent moisture and contaminants from entering.

- Follow the manufacturer’s guidelines regarding storage temperature and conditions.

- Understanding the shelf life of ep 0 grease and its impact on performance:

- Ep 0 grease has a limited shelf life, and using expired grease can lead to poor lubrication and potential equipment failure.

- Regularly check the expiration date on grease containers and discard any expired grease.

- Implement a first-in, first-out (fifo) approach when using stored grease to ensure fresh product usage.

Frequently Asked Questions On Ep 0 Grease Equivalent

What Is Ep 0 Grease Equivalent?

Ep 0 grease equivalent refers to a type of lubricating grease that has a low viscosity and is suitable for use in applications with low to moderate loads and temperatures. It provides excellent protection against wear and corrosion, ensuring smooth and efficient operation of machinery and equipment.

What Are The Applications Of Ep 0 Grease Equivalent?

Ep 0 grease equivalent is commonly used in types of industrial applications including automotive (John Deere and other mower bearings), industrial, and marine applications. It can be used in bearings, gears, couplings, and other mechanical components that require lubrication. It is especially suitable for applications where high water resistance and excellent oxidation stability are required.

How Does Ep 0 Grease Equivalent Compare To Other Greases?

Compared to other greases, ep 0 grease equivalent offers superior resistance to water washout and provides long-lasting protection against rust and corrosion and resistance. Its low viscosity ensures easy application and effective lubrication even in hard-to-reach areas. Additionally, ep 0 grease equivalent exhibits excellent adhesive properties, staying in place and reducing the need for frequent reapplication.

What is Type 0 grease?

Type 0 grease refers to NLGI Grade 0 grease, which has a semi-fluid consistency. It is often used in applications where a grease with good flow properties is required to ensure proper lubrication in hard-to-reach areas.

What is EP rating for grease?

The EP rating for grease stands for “Extreme Pressure” rating. It indicates a grease’s ability to withstand high-pressure and high-load conditions, preventing wear and damage in applications involving metal-to-metal contact.

What is the viscosity of EP 0 grease?

The viscosity of EP 0 grease can vary, but it typically falls within a range suitable for its NLGI Grade 0 consistency. It has a semi-fluid texture that allows it to flow and distribute effectively within machinery components.

What does EP mean in oil?

In the context of oil, EP stands for “Extreme Pressure.” It signifies an oil’s ability to provide lubrication under high-pressure conditions, often found in applications involving heavy loads and metal-to-metal contact, such as gears and bearings.

Best Practices for Switching Greases

When transitioning to an equivalent grease, consider the following best practices:

Gradual Transition

Introduce the new grease gradually, monitoring equipment performance and conducting regular inspections to assess any changes.

Regular Inspections

Schedule routine checks to evaluate the impact of the new grease on equipment performance and overall maintenance.

Record Keeping

Maintain a record of grease changes, performance improvements, or issues that arise after the transition. This documentation can be valuable for future reference.

Conclusion

Understanding the importance of finding the right grease for your machinery is crucial for optimal performance and longevity. By using an ep 0 grease equivalent, you can ensure that your equipment is well-lubricated and protected against extreme pressure and high temperatures.

This type of grease is specially formulated to handle heavy loads and provide excellent resistance to wear and corrosion. It not only reduces friction and prevents metal-to-metal contact but also extends the lifespan of your machinery, ultimately saving you time and money on repairs and replacements.