Enhance Performance with Dielectric Grease Spark Plug

Is dielectric grease necessary for spark plugs?

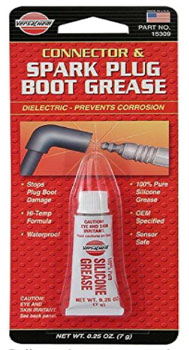

Dielectric grease can be beneficial when installing spark plugs, but it’s not strictly necessary. Dielectric grease is a silicone-based grease that is electrically insulating and seals out moisture.

Dielectric grease is not essential for every spark plug change, but it can be particularly helpful in:

Wet or salty environments: If your car frequently encounters rain, snow, or coastal conditions, the extra protection can be valuable.

Older engines: Older engines with less-than-perfect seals can benefit from the added moisture barrier. Difficult-to-reach spark plugs: If accessing the plugs is challenging, using grease can ease future removal.

Why use dielectric grease on spark plugs?

Protection: The main benefit is shielding the connection between the spark plug boot and the metal threads from moisture, corrosion, and vibration. This can extend the lifespan of both components and improve engine performance.

Sealing: A thin layer of grease can create a watertight seal around the base of the boot, preventing moisture from entering and causing misfires.

Lubrication: In some cases, grease can act as a lubricant during installation and removal, making it easier to slide the boot on and off the spark plug.

Here are some points to consider regarding the use of dielectric grease for spark plugs:

- Prevention of Corrosion: Dielectric grease can help prevent corrosion on the spark plug terminals. This is especially useful in areas with high humidity or where the vehicle is exposed to moisture.

- Easy Removal: Dielectric grease can make it easier to remove spark plug boots in the future. It prevents the boots from sticking to the porcelain insulator of the spark plug.

- Electrical Insulation: Dielectric grease provides electrical insulation, preventing arcing and ensuring a consistent flow of electrical energy from the ignition system to the spark plugs.

- High-Temperature Stability: It is designed to withstand high temperatures, which is crucial in the harsh environment around spark plugs.

However, it’s essential to apply dielectric grease correctly:

- Application on the Boot: Apply a small amount of dielectric grease inside the spark plug boot. This helps in preventing the boot from sticking to the spark plug and aids in future removal.

- Whether dielectric grease is necessary for spark plugs depends on several factors, including:

- Engine type: Some engines, particularly older models, may benefit from the additional protection against moisture and corrosion that dielectric grease provides. For newer engines with well-sealed ignition systems, it might not be as crucial.

- Spark plug type: Certain spark plug designs, like those with exposed metal threads, might benefit more from the insulating properties of dielectric grease. Consult your owner’s manual or the spark plug manufacturer’s recommendations for specific guidance.

- Environmental conditions: If your vehicle operates in wet or salty environments, using dielectric grease can offer valuable protection against corrosion and electrical shorts.

- Frequency of maintenance: If you tend to replace your spark plugs regularly, according to the manufacturer’s recommendations, using dielectric grease might not be as essential. However, for vehicles with extended spark plug change intervals, it can provide added peace of mind.

- Safety: Always practice caution when working on your vehicle’s electrical components. Consult a qualified mechanic if you’re unsure about any aspects of spark plug maintenance or the need for dielectric grease.

Where to put dielectric grease on spark plugs?

Applying dielectric grease to spark plugs can provide helpful protection against moisture and corrosion, but knowing where to place it is crucial for optimal performance and safety. Here’s a safe and effective guide:

Focus on the Thread Base:

- Apply a thin, pea-sized amount of dielectric grease to the base of the spark plug threads, where they meet the metal body. This area is most vulnerable to moisture and corrosion.

- Avoid putting grease on the tip of the spark plug electrode or inside the spark plug well, as this can disrupt ignition and cause misfires.

Here’s where you should apply dielectric grease on spark plugs:

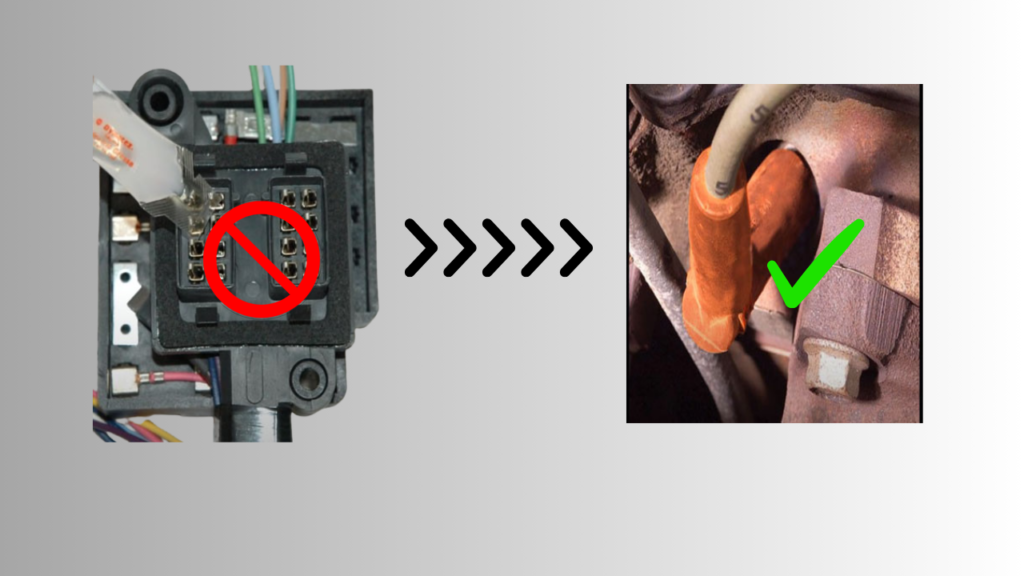

- Inside the Spark Plug Boot: Apply a small amount of dielectric grease to the inside of the spark plug boot. This helps in preventing the boot from sticking to the spark plug and aids in easy removal during future maintenance.

- Around the Terminal of the Spark Plug: Apply a thin, even coating of dielectric grease around the metal terminal of the spark plug. This provides a layer of protection against moisture and corrosion, ensuring a consistent electrical connection.

- Avoid Excessive Application: Do not apply excessive amounts of dielectric grease. A thin layer is sufficient for its intended purposes. Too much grease can lead to electrical interference and may attract dirt and debris.

- Do Not Apply to the Threads: Avoid applying dielectric grease to the threads of the spark plug. The threads need to make a secure mechanical connection with the cylinder head, and grease on the threads can interfere with proper torque application and heat dissipation.

- Apply During Installation: Apply the dielectric grease during the installation of the spark plugs. This ensures that the grease is in place from the beginning, providing protection against corrosion and facilitating future maintenance.

- Dielectric grease is particularly useful in areas with high humidity or where the vehicle is exposed to moisture. It helps to create a barrier against water intrusion, preventing the degradation of the spark plug connection over time.

Read More 5 Best Sealer For Saltillo Tile: Protect & Enhance Your Flooring

Dielectric grease spark plug Toyota

Too much dielectric grease on spark plugs – Effects on spark plugs

Applying too much dielectric grease on spark plugs can lead to several potential issues. While dielectric grease is beneficial in preventing corrosion and aiding in the easy removal of spark plug boots, excess grease can cause problems.

Here are some issues associated with using too much dielectric grease on spark plugs:

- Electrical Interference: Excessive dielectric grease can lead to electrical interference. This interference may affect the conductivity between the spark plug terminal and the ignition coil, potentially impacting the spark plug’s performance.

- Attracting Dirt and Debris: Too much grease can attract dirt, debris, and other contaminants. This buildup may compromise the effectiveness of the dielectric grease and could affect the electrical connection over time.

- Heat Dissipation Issues: Applying dielectric grease on the threads or in excess amounts may interfere with proper heat dissipation. Spark plugs generate heat during operation, and impeding heat dissipation can lead to overheating issues.

- Difficulty in Diagnostic Procedures: Excessive grease can make it challenging for mechanics or technicians to visually inspect spark plugs during diagnostic procedures. It may obscure potential issues, making it harder to identify problems with the spark plug or the combustion process.

How to apply dielectric grease?

Applying dielectric grease is a simple process, and it involves placing a thin, even layer in specific areas to ensure proper electrical insulation and protection against moisture.

Less is More: Remember, a little goes a long way! A pea-sized amount applied precisely is all you need.

Target the Base: Focus on the base of the connector’s threads, where they meet the metal body. This area is most vulnerable to moisture and corrosion. Avoid getting grease on the electrical contacts themselves, as this can disrupt connectivity.

Here’s a step-by-step guide on how to apply dielectric grease to spark plugs:

Materials Needed:

- Dielectric grease

- Clean, lint-free cloth

Procedure:

1. Gather Materials: Ensure you have the dielectric grease and a clean, lint-free cloth.

2. Clean the Spark Plug Terminal: Before applying dielectric grease, make sure the spark plug terminal is clean and free from dirt or debris. Use the cloth to wipe away any contaminants.

3. Apply Dielectric Grease to the Inside of the Spark Plug Boot: Squeeze a small amount of dielectric grease onto your fingertip. Apply the grease to the inside of the spark plug boot, spreading it evenly. This will prevent the boot from sticking to the spark plug and aid in future removal.

4. Apply Dielectric Grease to the Spark Plug Terminal: Apply a thin, even layer of dielectric grease around the metal terminal of the spark plug. Ensure that the entire terminal is covered with a light coating of grease. This provides electrical insulation and protection against moisture.

5. Avoid Excessive Application: Be cautious not to apply too much dielectric grease. A thin layer is sufficient for its intended purposes. Excessive grease can lead to electrical interference and attract dirt.

6. Do Not Apply to the Threads: Avoid applying dielectric grease to the threads of the spark plug. The threads need to make a secure mechanical connection with the cylinder head, and grease on the threads can interfere with proper torque application and heat dissipation.

7. Repeat for Each Spark Plug: Repeat the process for each spark plug you are installing or servicing.

8. Complete Installation: Proceed with the installation of the spark plugs as per the manufacturer’s guidelines.

Dielectric grease on coil pack

Applying dielectric grease to coil packs can be a helpful practice for protecting your ignition system from moisture and corrosion, but it’s important to do it correctly to avoid any issues. Here’s a safe and effective guide:

- Clean the Coil Pack: Before applying dielectric grease, make sure the coil pack surfaces are clean and free from dirt, debris, and old grease. Use a clean, lint-free cloth to wipe away any contaminants.

- Apply Dielectric Grease: Squeeze a small amount of dielectric grease onto your fingertip or a small brush suitable for precision application.

- Apply to Electrical Contacts: Apply a thin, even layer of dielectric grease to the electrical contacts on the coil pack. Ensure that the grease covers the metal contacts without excess buildup.

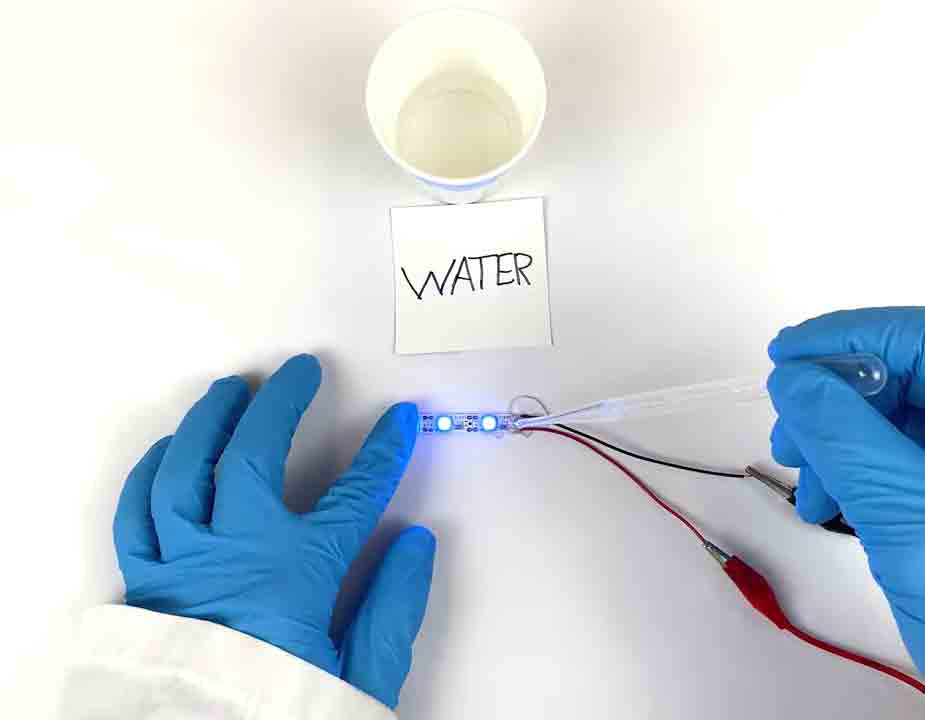

Is dielectric grease conductive?

While dielectric grease isn’t a perfect insulator, it’s certainly not a good conductor of electricity. Its primary function is as a protective barrier, shielding electrical connections from moisture, corrosion, and vibration. This protection, however, comes with a slight trade-off in electrical conductivity.

Here’s a breakdown of its conductivity properties:

Low conductivity: Compared to metals or pure copper, dielectric grease displays much lower conductivity. In most automotive and electrical applications, its conductivity is negligible and won’t impact circuit performance.

Impedance: However, it’s important to note that grease introduces some impedance to the electrical path. While usually minimal, this can become significant in high-frequency or high-precision applications.

Application matters: The amount applied also plays a role. A thin, controlled application poses minimal risk, while excessive grease can create conductive pathways, potentially causing issues.

Read More About 6 Best Thread Sealant For Hydraulic Fittings in 2024

What happens if you put dielectric grease on spark plugs?

1. Improved Electrical Connection: Dielectric grease on spark plugs enhances electrical conductivity and helps create a consistent and reliable electrical connection. It prevents the intrusion of moisture, which can cause corrosion and degrade the spark plug’s performance.

2. Prevention of Corrosion: Dielectric grease provides a protective barrier that helps prevent corrosion on the spark plug terminals. Corrosion can impede the flow of electrical current and lead to misfires or other ignition issues.

3. Ease of Removal: Applying dielectric grease aids in the easy removal of spark plug boots from the spark plugs. It prevents the boots from sticking to the spark plugs, facilitating smoother maintenance and replacement.

Using dielectric grease on spark plug wires

There are 2 kinds of purpose.

Applying grease to the spark plug wires themselves is generally not recommended. It can attract dirt and debris, potentially causing electrical problems. Stick to applying it at the base of the boots where it makes contact with the spark plug threads.

The other is opposite-

- Improved Connection: Dielectric grease on spark plug wires enhances the electrical connection between the wires and the spark plugs. It reduces the risk of misfires caused by poor conductivity.

- Moisture Protection: In wet or humid conditions, dielectric grease acts as a barrier against moisture, preventing it from reaching the spark plug wires and causing electrical issues.

- Prevention of Sticking: Applying dielectric grease on spark plug wires helps prevent the boots from sticking to the spark plugs. This aids in easy removal during maintenance.

Changing spark plugs without dielectric grease

- Risk of Sticking: Without dielectric grease, spark plug boots may stick to the spark plugs, making removal more challenging during future maintenance.

- Increased Corrosion Risk: The absence of dielectric grease may increase the risk of corrosion on the spark plug terminals, potentially leading to electrical issues.

Dielectric grease on spark plug tip:

- Avoiding Application: Dielectric grease should not be applied directly to the spark plug tips or threads. It is meant for insulating and protecting electrical connections, not the areas where mechanical contact and heat dissipation occur.

- Recommended Areas: Focus on applying dielectric grease to the inside of spark plug boots and around the metal terminals to ensure proper functionality.

When not to use dielectric grease

While dielectric grease is beneficial in many electrical applications, there are situations where its use may not be appropriate or may even be detrimental. Here are some scenarios when you might want to avoid using dielectric grease:

Spark Plug Threads: Do not apply dielectric grease to the threads of spark plugs. The threads need to make a secure mechanical connection with the cylinder head, and grease on the threads can interfere with proper torque application and heat dissipation.

Sensor Connections: Avoid using dielectric grease on sensor connections, such as oxygen sensors or mass airflow sensors. Some sensors rely on direct metal-to-metal contact for proper function, and dielectric grease may interfere with their signals.

ABS (Anti-lock Braking System) Sensors: Similar to sensors, avoid applying dielectric grease to ABS sensor connections. Dielectric grease can potentially interfere with the signals transmitted by ABS sensors.

Battery Terminals: Dielectric grease should not be applied to battery terminals. Battery terminals require a clean, metal-to-metal connection for optimal electrical conductivity. Dielectric grease can impede the flow of current.

Ignition Coils: Some ignition coil designs may not benefit from the application of dielectric grease. It’s essential to check the manufacturer’s recommendations for specific coil designs.

Light Bulb Connections: Avoid using dielectric grease on light bulb connections, especially in automotive lighting systems. Dielectric grease may not be suitable for use with certain bulb types or could affect electrical connections.

High-Voltage Contacts: Dielectric grease may not be suitable for high-voltage applications, such as those involving extremely high voltage levels or specialized electrical equipment. Consult the manufacturer’s guidelines in such cases.

Electronic Components with Direct Metal-to-Metal Contact: In applications where direct metal-to-metal contact is required for electronic components to function correctly, dielectric grease should be avoided.

Certain Switches: In some cases, the use of dielectric grease on certain types of switches may interfere with their mechanical operation. Always refer to the manufacturer’s recommendations for specific components.

Certain Connectors with Tight Tolerances: Some connectors with very tight tolerances may not be designed to accommodate the use of dielectric grease. It’s essential to consider the design and specifications of the connectors involved.

Read Also 6 Best Liquid Rubber Foundation Sealants for Ultimate Protection

FAQ

Should dielectric grease be used on spark plugs?

Yes, dielectric grease is recommended for spark plugs. It prevents corrosion, aids in easy removal, and improves electrical connections by providing insulation and moisture resistance.

Can dielectric grease cause a misfire on spark plugs?

No, when applied correctly, dielectric grease prevents misfires by insulating and protecting spark plug connections from moisture and corrosion. It enhances reliability and electrical conductivity.

What grease can I use on spark plugs?

Use dielectric grease on spark plugs. It insulates, prevents corrosion, and aids in removal. Avoid using regular grease, as it may impede electrical conductivity and cause issues.

What is dielectric grease used for?

Dielectric grease is used to insulate electrical connections, prevent corrosion, and enhance conductivity. Commonly used in spark plug boots, connectors, and electrical components to protect against moisture.

Does dielectric grease improve connection?

Yes, dielectric grease improves electrical connections by preventing corrosion, insulating contacts, and resisting moisture. It ensures a reliable and efficient flow of electricity in various electrical components.

Does dielectric grease increase connection?

Dielectric grease doesn’t increase the electrical connection’s strength but improves reliability by preventing corrosion and maintaining optimal conductivity. It aids in consistent electrical performance over time.

Is spark plug boot protector dielectric grease?

The spark plug boot protector is similar but not the same as dielectric grease. While both protect against moisture, dielectric grease additionally insulates and improves electrical conductivity, enhancing overall spark plug performance.

Conclusion

In conclusion, the application of dielectric grease on spark plugs is a prudent practice. By preventing corrosion, aiding in removal, and improving electrical connections, dielectric grease ensures optimal spark plug performance. Its insulating properties and resistance to moisture make it an invaluable component in maintaining reliable ignition systems. For those seeking longevity and efficiency in spark plug functionality, incorporating dielectric grease remains a key recommendation in automotive maintenance.