Loctite Blue Vs Red: Which Loctite is the Strongest?

WHAT’S THE DIFFERENCE BETWEEN RED AND BLUE LOCTITE THREADLOCKER?

The difference between red and blue threadlocker is a matter of versatility, strength and removability balance. Loctite blue is a medium-strength threadlocker easily be replaceable with common tools, while Loctite red is a full high-strength, permanent fix threadlocker.

Loctite threadlockers are indispensable companions in the world of fastening, offering a spectrum of choices to meet diverse needs.

Loctite blue and Loctite red are two well-known thread lockers used in industries to provide a secure, permanent bond between threaded parts. Let’s check RECOMMENDED PRODUCTS:

Loctite Threadlocker Blue 242 emerges as the unsung hero. From crucial car parts like oil pans and water pumps to the intricate world of motorized yard equipment, this threadlocker is the linchpin that ensures stability and durability in the face of constant vibrations and mechanical stress.

The main difference between Loctite Blue vs red is that Loctite Blue is easier to remove and provides medium-strength thread locking, suitable for most applications where you want to prevent fasteners from coming loose but still need to disassemble them without excessive effort.

Loctite Red 271 is the adhesive of choice for structural bolts in homes, where stability and permanence are non-negotiable. From the framework to foundational components, this red threadlocker ensures a rock-solid connection, contributing to the long-term integrity of the structure.

Loctite Red offers a stronger bond but is harder to remove by hand tool, making it better suited for applications where a more robust lock is required and making it hard to disassemble components in the future.

For applications involving less frequent disassembly, particularly for bolts larger than M6, Loctite 243 stands out as the preferred choice. This medium-strength product offers a balance of reliable bonding and ease of removal when needed. Notably, Loctite 243 surpasses its counterpart, Loctite 222(1800C vs. 1500C), in terms of both oil tolerance and temperature resistance.

Red Loctite cure time:

The cure time for Red Loctite can range from several hours to 24 hours or more. While an initial cure may occur relatively quickly, Red Loctite continues to cure over an extended period. Full strength is typically achieved after 24 hours or longer.

Let’s Check Threadlocker: Red or blue, which one is right for you?

Loctite Blue Vs Red Threadlocker: Comparison Table

Here’s a table summarizing their key characteristics and later check Loctite grades chart:

| Property | Loctite Blue | Loctite Red |

| Strength | Medium,Suitable for bolts larger than M6 | Medium, Suitable for heavy-duty applications |

| Recommended Applications | General household use, automotive parts, furniture, pumps, etc. | Disassemble the components |

| Bonding Type | Temporary | Permanent |

| Variants | 242, 243, 248, 2432 | 263, 268, 271, 272 |

| Removal Procedure | Can be disassembled with household tools | Requires heat and often chemical combinations |

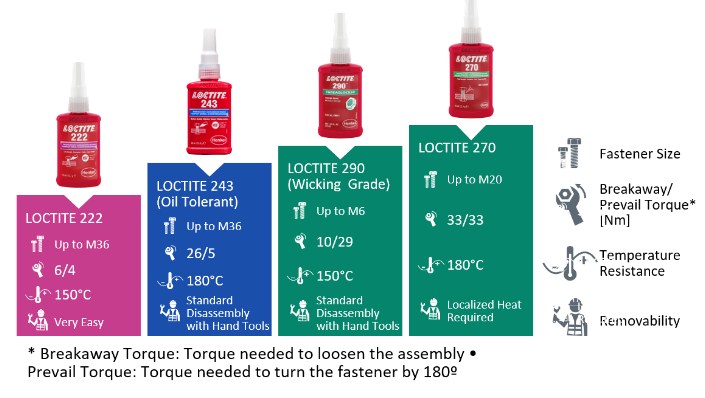

Loctite color strength chart: Loctite comparison chart

High strength loctite threadlocker chart

Also Read: Freestyle Libre Adhesive Patches

What Does Blue Loctite Mean?

Blue Loctite refers to a medium strength thread locker adhesive used to secure fasteners like studs, screws and bolts. It prevents them from loosening due to vibrations or stress but allows for disassembling components, making it ideal for furniture assembly, especially when using 20 mm screws.

How strong is blue Loctite?

Strength:

- Medium strength: Blue Loctite offers a reliable and robust bond suitable for a wide range of applications.

Removability:

- Removable with hand tools: Unlike high-strength threadlockers (such as Red Loctite) that may require heat or special tools for removal, Blue Loctite can be disassembled using common hand tools.

What Does Red Loctite Mean?

Red Loctite, specifically Loctite 262, is a high strength adhesive designed for permanent bonding. It’s a thread locker used to secure threaded assemblies, preventing loosening due to vibration or shock, and ensuring a secure, lasting connection.

Loctite Blue Vs Red: Application

Loctite Blue and Loctite Red are two different types of threadlocker adhesives produced by the Loctite Corporation.

What Is Blue Loctite Used For?

You can use blue Loctite threadlocker for different purposes:

- For securing bolts and nuts.

- It prevents leakage of fluids through thread gaps.

- Blue threadlockers protect parts like car brake rotors from parts from rust and corrosion.

- Resistant to vibration and shock

- It aids in preventing accidental disassembly.

- Quick application and cures in approximately 24 hours.

What Is Red Loctite Used For: when to use red Loctite?

Red Loctite is a high-strength adhesive. You can use red for:

- It is used for the permanent locking of threaded fasteners.

- Commonly used in applications where high vibration or heat may cause loosening.

- Ideal for securing nuts and bolts.

- Provides a strong, reliable bond that is difficult to disassemble.

- Offers a secure and lasting connection in various industrial and automotive settings.

Red And Blue Loctite Threadlocker: Temperature Range

Red and Blue Loctite Threadlockers offer reliable performance in a wide temperature range, from -55°C to +150°C. Red Threadlocker can withstand temperatures up to +232°C, making it ideal for high-heat applications, while Blue Threadlocker is suitable for temperatures within the -55°C to +150°C range, ensuring secure and durable fastening in various conditions.

Red vs Blue Threadlocker: Durability

Both remain effective 12 months after opening and up to 24 months when unopened, ensuring reliable performance in various applications. Choose wisely based on your project needs.

Loctite 242 vs Loctite 271 Effectiveness Under Water

Loctite 242 and Loctite 271 are both effective for various applications, but they are not waterproof. Whether it is red or blue never use loctite either underwater, as they are not designed for submersion.

What Is The Difference Between Red And Blue Loctite Strength?

The difference between red and blue Loctite strength lies in their respective applications. Red Loctite is the strongest threadlocker, providing a high-strength bond. It requires localized heat to disassemble.

In contrast, blue Loctite is medium-strength, blue works well in preassembled fasteners without excessive force, and can be removed without heat, offering more versatility in assembly and disassembly tasks.

Loctite Blue Vs Red: Advantages

Loctite Blue (Threadlocker 242)

- Removability: Easier to disassemble than Loctite Red, making it suitable for applications where occasional maintenance or disassembly is required.

- Medium Strength: Provides sufficient resistance to high torque, vibrations and loosening while allowing for manual disassembly with standard hand tools.

- Versatility: Suitable for a wide range of fasteners and materials, including metals and plastics.

- Color-Coding: Blue color for easy identification.

Loctite Red (Threadlocker Red 271):

- Maximum Strength: Offers the highest level of threadlocking strength among Loctite products, providing exceptional resistance to vibrations and loosening.

- Permanent Bond: Designed for applications where permanent or semi-permanent assembly is desired, making it ideal for critical fasteners that should never come loose.

- Limited Removability: While it can be disassembled with the application of heat and hand tools, it is more challenging to remove than Loctite Blue.

Factors That Affect The Performance Of Loctite Blue And Red

- The performance of Loctite Blue and Red thread lockers can be affected by various factors, including:

- Temperature: Extreme temperatures, both high and low, can impact the curing and strength of the threadlocker.

- Humidity: High humidity levels can affect the curing process and may require longer curing times.

- Cleanliness: Properly cleaning and degreasing the threads before applying the thread locker is essential for adhesion and effectiveness.

- Surface Roughness: The roughness of the mating surfaces can influence the thread locker’s ability to bond.

- Amount Applied: Using too much or too little thread locker can affect its performance. Follow manufacturer guidelines for the correct amount.

- Material: The type of materials the threadlocker is applied to (e.g., steel, aluminum, plastic) can impact its effectiveness.

- Thread Size: Larger 22 mm or irregular thread sizes 6 mm may require different thread locker formulations.

Read Also Cpvc Vs Pvc Glue : Which One is Stronger for Your Plumbing Needs?

How to Apply Thread Locker

To apply threadlocker, follow these steps:

- Ensure the threaded parts are clean and dry.

- Choose the appropriate Loctite threadlocker for your application (e.g., blue 242 for medium-strength).

- Shake the threadlocker bottle.

- Apply the threadlocker to the threads.

- Use a certain amount to ensure coverage but avoid excessive application.

- Assemble the parts and tighten as needed.

- Allow the threadlocker to cure according to the product’s instructions.

- Clean any excess threadlocker for a near finish.

How to Remove Loctite® Threadlocker

Material Required

- Blowtorch

- Safety glasses

- Chemical named cyanoacrylate

- Wrench

To remove Loctite® Threadlock, follow these steps care fully:

- Prepare: Ensure the threaded components are at room temperature and cured fully.

- Apply Heat: Use a heat source like a propane torch to heat the threaded area evenly. Aim for temperatures around 450°F (232°C).

- Apply Torque: After heating, use a wrench to apply torque in the counterclockwise direction to break the cured bond. Be patient and firm but avoid excessive force.

- Clean Thoroughly: Once the threadlocker is loosened, clean the threads with a wire brush and solvent to remove any residue.

- Inspect and Repeat: Inspect the components, and if necessary, repeat the process until the Loctite® Threadlocker is completely removed.

Factors to Consider When Choosing Loctite Color

When choosing the right Loctite color for your project, consider the following factors:

- Material Compatibility: Ensure that the Loctite adhesive is compatible with the materials you are bonding, as different colors may have different formulations.

- Cure Time: Consider the required curing time, as some colors may set faster than others.

- Visibility: Opt for a color that blends well with the materials or one that provides easy visual confirmation of the adhesive application.

- Temperature Resistance: Check if the selected color can withstand the temperature conditions your project will encounter.

- Application Method: Choose a color suitable for your preferred application method, such as brush, squeeze tube, or syringe.

- Industry Standards: Comply with industry-specific requirements that may dictate the use of specific Loctite colors.

- Testing: If uncertain, conduct a small-scale test to ensure the selected color meets your project’s requirements.

As with any chemical product, it’s important to take certain precautions and safety measures when using loctite blue or red. Here are some of the most important ones:

Short notes

- Loctite blue:

- Automotive and marine repairs

- Electrical and electronic repairs

- Small-sized fasteners

- Metal surfaces

- Loctite red:

- Heavy-duty applications

- Engineering and construction

- Large-diameter fasteners

- Industrial machinery

Benefits Of Using Loctite Brand Adhesives

Loctite has been a trusted name in adhesives since 1956 and offers a range of products to meet different needs. Here are some benefits of using loctite brand adhesives:

- Loctite provides a high level of strength and durability for various materials, including metal, plastic, and rubber.

- Their adhesives are resistant to vibration, impact, temperature, and other harsh conditions, ensuring a long-lasting hold.

- Loctite adhesives come in different forms, including liquids, gels, and pastes, making them versatile and easy to apply for different applications.

Read Also Battle of the Adhesives: Krazy Glue vs Nail Glue

Additional Resources For Learning More About Loctite Blue And Red

If you want to know more about loctite’s blue and red products, there are plenty of resources available online and offline. Here are some recommended links:

- Loctite’s official website: Https://www.loctite.com/en/home.html

- Youtube videos showcasing loctite blue and red in action: Https://www.youtube.com/results?search_query=loctite+blue+vs+red

- Online forums dedicated to discussions on adhesives and their properties: Https://www.finishing.com/295/37.shtml.

Frequently Asked Questions Of Loctite Blue Vs Red

What is the weakest color of Loctite?

The weakest color of Loctite is typically purple. It represents a lower-strength adhesive compared to other colors, suitable for applications where disassembly may be required.

What breaks red Loctite 271?

Red Loctite can be broken by applying heat above 250°C (550°F). This high temperature weakens the adhesive bond, making it easier to disassemble parts.

Does WD 40 remove Loctite?

WD-40 can help loosen Loctite bonds to a certain extent but for a more reliable removal. Use certain amount of Methylene Chloride-based solvents designed for this purpose.

What is the curing time of locktite?

The curing time of Loctite varies depending on the specific product, but it typically ranges from a few minutes to around 24 hours for complete bond strength to develop.

Which Loctite threadlockers come with high adhesion strength?

Green Loctite threadlockers are known for their high adhesion strength, providing reliable and durable bonds for various applications where robust locking performance is essential.

Which is the strongest loctite?

The strongest Loctite adhesive is typically considered to be Loctite 638, a high-strength retaining compound. It’s designed for applications requiring exceptional bond strength and resistance to vibration.

Can I Apply Loctite Blue Over Loctite Red?

No, you can’t. Loctite red has a higher holding strength than blue and requires heat for removal. Applying blue over red will weaken the bond, causing the assembly to fail. Always use the same formula of loctite when reapplying or adjusting a joint.

How Long Does It Take For Loctite To Dry?

Loctite dries between 10 and 20 minutes, depending on the formula and the environmental conditions. The optimal drying temperature is 21°c. However, it can take up to 24 hours to achieve full strength. Avoid using the assembly until the bond is fully cured.

Can Loctite Be Used On Plastic?

Yes, loctite is suitable for use on plastic materials. However, you should choose a formula specifically designed for plastic bonding. Loctite plastics bonding system is ideal for bonding plastics, including pvc, polycarbonate, and acrylics. Always follow the instructions on the label.

Is It Safe To Use Loctite Indoors?

Yes, it is safe to use loctite indoors as long as you follow the safety precautions indicated on the label. You should ensure there is enough fresh air circulating the working area to avoid inhaling the fumes. Wear protective clothing, goggles, and gloves when handling loctite.

Also Read: Green Glue Vs Mass Loaded Vinyl

Conclusion on Threadlocker Adhesives

After thoroughly discussing Loctite blue and Loctite red, it is clear that both products are effective in their own ways. Loctite blue is ideal for small screws, bolts, and nuts, while loctite red is suitable for larger bolts and studs. We also discuss the loctite threadlocker chart and Loctite strength chart.

However, it’s important to note that loctite red requires heat to be removed, whereas loctite blue can be removed with a standard tool. Understanding the specific needs of your project is crucial to selecting the appropriate loctite product. In terms of performance, both options provide excellent results in preventing loosening and leakage.

In conclusion, when it comes to adhesive solutions, the choice between Loctite Blue vs Red can make all the difference for a better experience. Selecting the right one ensures your projects stay secure and dependable.