Chevron Grease Compatibility Chart: Find the Perfect Lubricant Match!

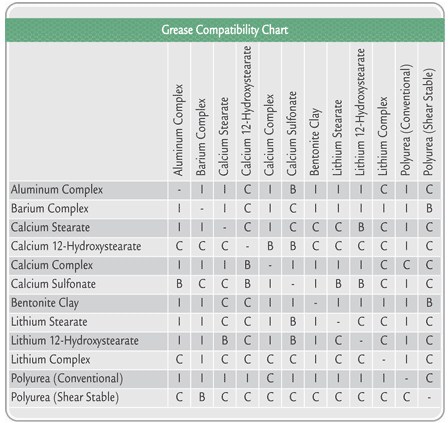

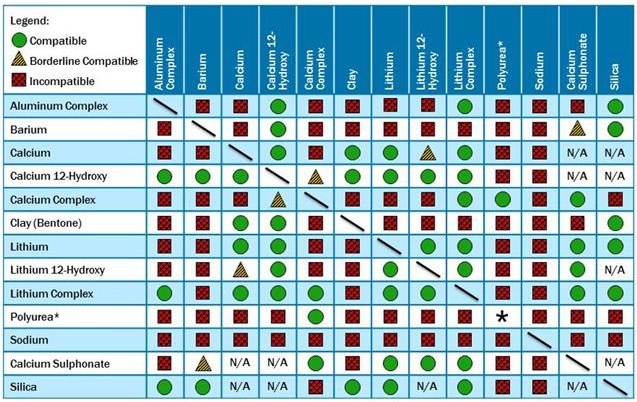

The Chevron grease compatibility chart provides accurate information on the compatibility of different grease products. You will find a concise overview of the chart, including its importance and how it can be used in various industrial applications.

When it comes to selecting the right grease for your industrial machinery, compatibility is crucial. Using incompatible greases can lead to equipment damage, reduced performance, and costly repairs. The chevron grease compatibility chart is a valuable resource that helps users identify which greases are compatible with each other, ensuring optimal performance and protection for your equipment.

This comprehensive chart categorizes different greases based on their thickener types and provides clear compatibility guidelines. It allows users to quickly and accurately determine which greases can be mixed or should be kept separate.

Its accurate and concise information allows users to make informed decisions, ensuring the best performance and protection for industrial machinery.

How Do You Know If Greases Are Compatible?

- Check the compatibility of lubricating greases by consulting a cross-reference chart or database.

- Refer to manufacturer specifications to ensure compatibility between different grease types.

- Consider the base oil and thickener type when evaluating compatibility.

- Assess the NLGI (National Lubricating Grease Institute) grade to ensure it matches for proper consistency.

- Compatibility testing may be necessary when switching greases to prevent adverse reactions.

- Look for any compatibility warnings or recommendations in the product documentation.

- Avoid mixing greases with significantly different properties to prevent performance issues.

- Consult with a lubrication expert or manufacturer for guidance on grease compatibility.

Is Lithium And Polyurea Grease Compatible?

Lithium and polyurea grease are generally compatible, making them suitable for various mechanical applications. Polyurea grease offers superior mechanical stability, ensuring long-lasting lubrication. Its advanced formulation helps maintain consistent parameters over time.

Which Is Better Polyurea Or Lithium Grease?

While lithium grease is a reliable choice, polyurea grease is often considered a better option due to its enhanced mechanical stability, making it a preferred solution for applications demanding exceptional reserve lubrication capabilities. Ultimately, the choice between the two depends on specific mechanical requirements.

Chevron Sri Grease Nlgi 2 Equivalent

Chevron Black Pearl® Grease EP is an NLGI 2 equivalent lubricant. This high-quality grease offers excellent extreme pressure (EP) and anti-wear properties, making it ideal for various industrial and automotive applications. Its advanced formulation ensures long-lasting lubrication and protection against wear and corrosion, ensuring smooth and efficient equipment operation.

Chevron Sri 2 Grease Specification

Chevron Sri 2 Grease is ideal for high-speed operations with temperatures from -30°C to 177°C. It offers excellent oxidation stability, ensuring long bearing life at temperatures of 93°C to 177°C. This grease also provides top-notch rust protection, meeting ASTM D5969 standards with 10% Sea Water, keeping your equipment corrosion-free.

Is Mobilux EP Shell the same as Chevron Grease?

No, Mobilux EP Shell and Chevron Grease are not the same products. They are both grease lubricants, but they are produced by different companies and may have distinct formulations and properties. Mobilux EP Shell is manufactured by Shell, while Chevron Grease is produced by Chevron. It’s important to use the specific grease recommended for your equipment to ensure proper lubrication and performance.

Understanding Compatibility

The Significance Of Grease Compatibility In Machinery Operation

- Using incompatible greases in your machinery can lead to issues such as reduced lubrication efficiency, equipment breakdowns, and increased maintenance costs.

- Compatibility ensures that the greases you use will not adversely affect each other’s performance when combined in the same system.

- It allows for proper lubrication and protects your machinery against wear, corrosion, and damage caused by friction.

Factors That Influence Compatibility Of Lubricants

Base oil type:

- Different base oil types have varying chemical compositions, properties, and performance characteristics.

- Compatibility between greases depends on the similarity or compatibility of their base oil types.

- Ideally, greases with the same or similar base oil types should be used together to ensure compatibility.

Thickeners and additives:

- The thickener used in grease formulation affects its structure, consistency, and behavior.

- Incompatible thickeners can lead to softer or harder grease, causing inadequate lubrication.

- Additives in greases can also affect compatibility, as different additives may not work well together or may produce undesired reactions.

To summarize, understanding grease compatibility is essential for maintaining machinery efficiency and preventing costly breakdowns. The compatibility of lubricants is influenced by the base oil type, thickener, and additives used. By selecting compatible greases and ensuring proper lubrication, you can ensure the smooth operation and longevity of your machinery.

Chevron Grease Compatibility Chart: An Overview

Organization Of The Chart:

- The chevron grease compatibility chart is organized based on the compatibility of different grease types.

- It categorizes greases into four main types: Lithium, lithium complex, calcium, and polyurea.

- Each grease category is further divided into several subcategories based on specific properties and applications.

Categories And Color Codes:

- Lithium greases, represented by the color blue in the compatibility chart, are widely used due to their versatility and excellent performance in various applications.

- Lithium complex greases, indicated by the color green, are high-performance greases suitable for heavy-duty applications and extreme conditions.

- Calcium greases, identified by the color brown, are commonly used in automotive and general-purpose applications.

- Polyurea greases, characterized by the color red, offer superior performance and stability, making them ideal for high-speed applications.

Compatibility Ratings And Symbols:

- The chevron grease compatibility chart assigns compatibility ratings to different grease combinations to help users select appropriate lubricants.

- The compatibility ratings range from “excellent” to “not recommended,” providing a clear indication of the compatibility between different grease types.

- The chart also uses symbols such as “+” (compatible), “-” (not compatible), and “o” (performing tests before use) to facilitate quick identification and decision-making.

Read More About B7000 Glue Vs E6000: A Comprehensive Comparison

How To Use The Chevron Grease Compatibility Chart

Step-By-Step Guide On Navigating And Utilizing The Chart Effectively

Identifying The Lubricant From The Starting Point

- Start with the starting point: The chart features a starting point, labeled as the chevron delo grease ep2. Look for this point as it will serve as the foundation for your compatibility search.

- Understand the compatibility arrows: The chart is filled with arrows that indicate which lubricants are compatible with each other. The arrows depict a flow of compatibility, guiding you to compatible lubricants.

- Follow the arrows: To determine the compatibility of a specific lubricant with others, follow the arrows from the starting point. As you identify the desired lubricant, you will find arrows leading to other compatible lubricants.

- Pay attention to the color-coded labels: The chart uses different colors to classify the compatibility of each lubricant. Green indicates full compatibility, yellow suggests limited compatibility, and red marks incompatibility. Make sure to choose lubricants with full or limited compatibility to ensure the best performance.

- Consider the arrow types: The chart features two types of arrows – solid arrows and dashed arrows. Solid arrows indicate direct compatibility between two lubricants, while dashed arrows signify limited compatibility through the use of an intermediate lubricant. Take note of these arrow types as you make your lubricant selection.

- Double-check compatibility: Always cross-reference the lubricant you have identified with the chart to ensure compatibility with other lubricants in your machinery. This step is crucial to prevent any adverse effects or potential damage to your equipment.

Also Read: Green Glue Vs Mass Loaded Vinyl

Key Takeaways From The Compatibility Chart

Understanding The Results And Their Implications

The chevron grease compatibility chart provides crucial information about which lubricants are compatible and which ones should never be mixed. Here are the key takeaways from the chart:

- The compatibility chart categorizes lubricants into three main groups: Compatible, marginally compatible, and incompatible. Compatible greases are safe to use together, while marginally compatible ones require special attention to ensure optimal performance. Incompatible greases, on the other hand, should never be mixed under any circumstances.

- The compatibility chart often highlights specific lubricant combinations that are commonly used together.

Compatible Lubricants And Their Usage Scenarios

Understanding which lubricants are compatible opens up possibilities for the safe and effective use of greases. Here are some essential points to remember about compatible lubricants and their usage scenarios:

- Compatible lubricants, as indicated by the chart, can be mixed without any adverse effects. This allows for easier maintenance and reduces the risk of using the wrong lubricant during servicing. It also offers the flexibility to combine different greases for specific applications, depending on your equipment requirements.

- Using compatible lubricants improves equipment longevity, performance, and reliability. By following the compatibility chart and using compatible greases, you can ensure that your equipment operates smoothly, minimizing wear and tear and extending its lifespan.

- Different lubricants have specific properties that make them suitable for various scenarios. Understanding compatibility enables you to select the right grease for each application, whether it’s high-temperature environments, extreme pressures, or specialized equipment. This helps in achieving optimal performance and reducing equipment downtime.

Incompatible Combinations And Their Risks

The chevron grease compatibility chart also highlights combinations that should never be mixed due to their incompatibility. Here are the risks associated with using incompatible combinations:

- Mixing incompatible greases can lead to chemical reactions and complex formations. These reactions can alter the lubricating properties, leading to reduced effectiveness, poor performance, and even equipment failure. The resulting side effects can range from increased friction and wear to severe damage and system breakdowns.

- Incompatible combinations can cause lubricant degradation, resulting in sludge or varnish formation. This can clog critical components, restrict fluid flow, and prevent proper lubrication. The compromised performance can affect the efficiency and functionality of your equipment, leading to additional maintenance or replacement costs.

- Mixing incompatible lubricants may void equipment warranties and approvals.

Faqs About Chevron Grease Compatibility

Are all greases compatible with each other?

It’s important to note that not all greases are compatible with each other. Different greases have different formulations, and using incompatible greases can lead to reduced performance and potential damage to your equipment.

Can i mix different brands of greases?

Mixing greases from different brands is generally not recommended. Each brand may have its unique formulation, additives, and base oil types. Mixing incompatible greases can result in unpredictable chemical reactions, leading to decreased performance and potential equipment damage.

What happens when incompatible greases are mixed?

When incompatible greases are mixed, the combination may result in a change in the properties of both greases. This can lead to a decrease in lubrication effectiveness, increased friction, and even the formation of harmful deposits within the equipment.

How can i determine if two greases are compatible?

To determine the compatibility of two greases, it is essential to consult the manufacturer’s recommendations and compatibility charts. These charts provide valuable information about the compatibility of different greases based on their formulations.

Can i continue using the same grease if i switch to a different brand?

Switching to a different brand of grease should not pose compatibility issues as long as the new grease is compatible with the equipment and application requirements. However, it is always best to consult the manufacturer’s recommendations and compatibility charts to ensure a smooth transition.

What if i accidentally mix incompatible greases?

If incompatible greases are accidentally mixed, it is crucial to remove as much of the mixed grease as possible. This can be done by cleaning the equipment and replacing the mixed grease with the correct grease recommended by the manufacturer. Regular inspections and maintenance will help prevent accidental mixing in the future.

sing the chevron grease compatibility chart to avoid lubrication issues. By following the recommended guidelines, businesses can ensure proper compatibility, minimize equipment failures, and optimize overall performance. Remember, it’s crucial to consult the compatibility chart for accurate lubrication decisions, ultimately saving time, money, and resources.

Frequently Asked Questions Of Chevron Grease Compatibility Chart

What Is A Chevron Grease Compatibility Chart?

A chevron grease compatibility chart is a tool that helps users determine which greases are compatible with each other. It provides information on which greases can be mixed together without causing any negative effects on performance or properties.

Why Is A Grease Compatibility Chart Important?

A grease compatibility chart is important because incompatible greases can lead to reduced lubrication effectiveness, increased wear, and potential equipment failure. By using a compatibility chart, users can ensure they are using the right greases that will work well together, maintaining optimal equipment performance and extending component life.

How Does A Grease Compatibility Chart Work?

A grease compatibility chart works by categorizing greases into different compatibility groups based on their base oil type and thickener type. Each group indicates whether the greases can be mixed together safely or if there may be compatibility issues. Users can easily find the appropriate compatibility group for their greases and determine if they are compatible or not.

Can I Mix Greases From Different Compatibility Groups?

It is generally not recommended to mix greases from different compatibility groups as they may have different chemical compositions that can lead to detrimental effects like thickening, separation, or loss of performance. However, if mixing is necessary, it is advisable to consult with the grease manufacturer or refer to the compatibility chart for specific guidance.

What Are The Potential Consequences Of Using Incompatible Greases?

Using incompatible greases can result in poor lubrication, increased friction, excessive heat, accelerated wear, and potential damage to components. These consequences can lead to decreased equipment efficiency, costly repairs, and unplanned downtime. It is crucial to adhere to grease compatibility guidelines to maintain optimal equipment performance and reliability.

Conclusion

Understanding the chevron grease compatibility chart is essential for anyone involved in maintenance or machinery operations. With the wide range of greases available, it’s crucial to select the right one to ensure optimal performance and prevent equipment damage. By referring to the compatibility chart, you can make informed decisions and avoid mixing incompatible greases, which can lead to reduced effectiveness and potential breakdowns.

This resource provides valuable information on the compatibility of chevron greases with different types of additives, thickeners, and base oils. Being aware of the chemical composition and properties of these greases allows you to choose the most suitable product for your specific application.

Ultimately, utilizing the chevron grease compatibility chart helps to extend the lifespan of your machinery and maintain its efficiency, saving you time and money in the long run.

https://www.machinerylubrication.com/Read/29337/understanding-grease-compatibility